Ok, Jerome you are in for a ride, so hold on lol. There are three versions of this machine with only slight differences in the control panel wording.

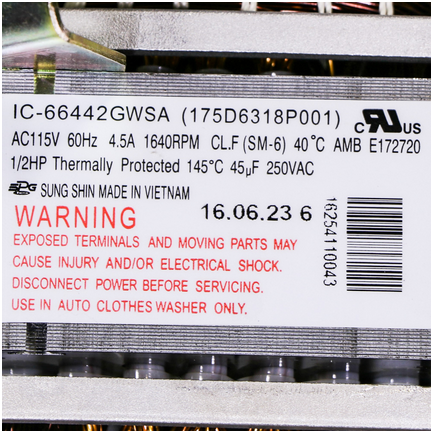

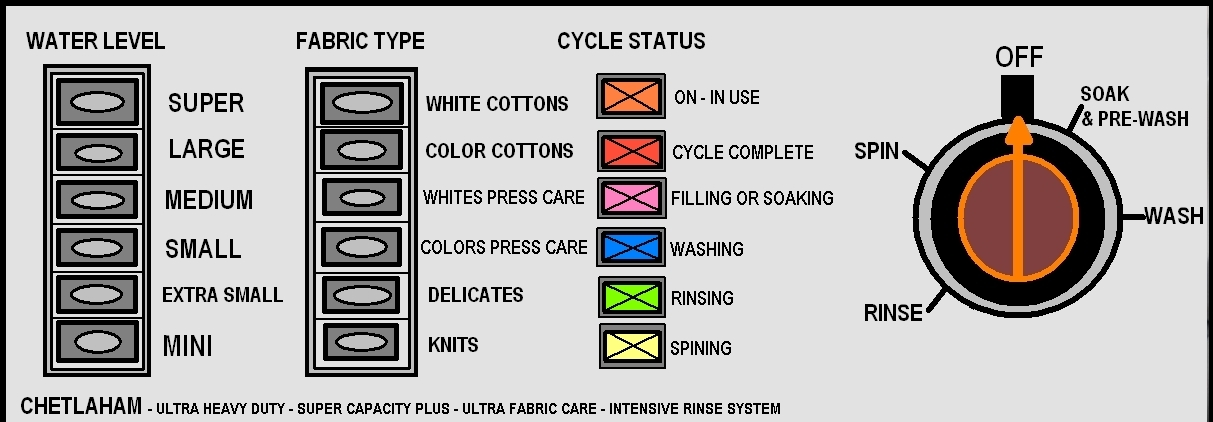

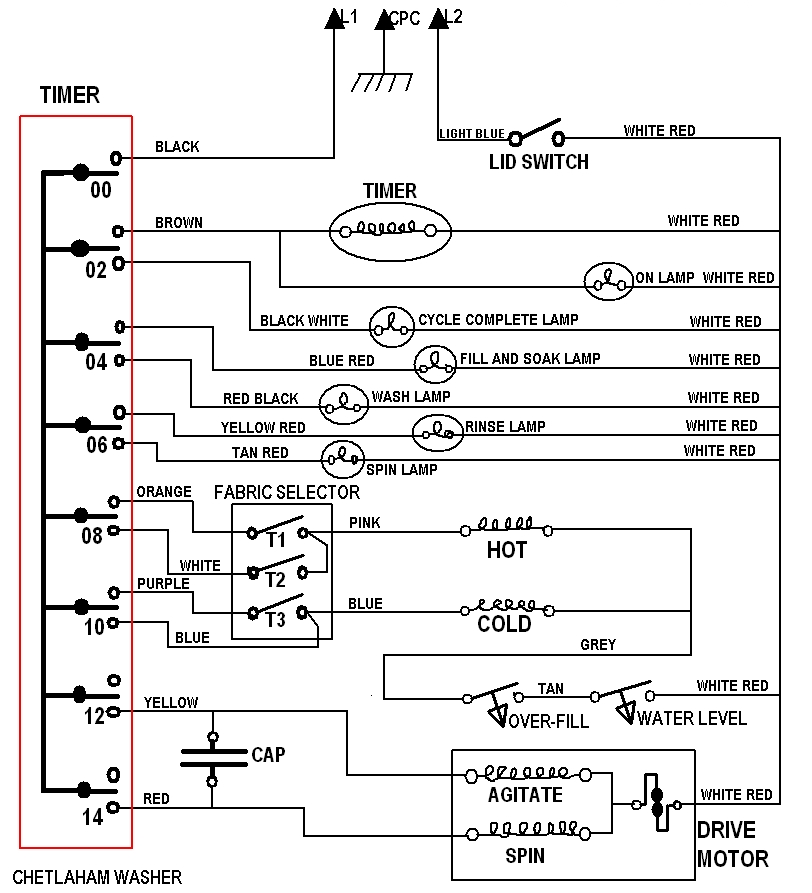

First is a single speed model with a 4 pole 1650 RPM motor. All cycle times and functions are identical. The only thing the fabric type switch does is control the wash and rinse water temperatures. That is it. As a result, delicate is relabeled to bright colors and knits to hang dry to reflect the fact there is no real delicate cycle on this machine. Permanent Press is called whites press care or sheets and colors press care or easy care or casuals in that other than a cold spray, there is no genuine half tub drain or slow / shortened spin. Not that calling it press care would be truly deceptive, there are many machines out there today that call a 10 second spray with a 6 minute high speed spin identical to the heavy cycle cycle a full blown permanent press cycle. I have yet to see anyone notice. I have included a wiring diagram of this one speed machine in that it is relatively simple and straightforward as to what is going on behind the knobs.

Second model is also a single speed model model with the same 4 pole motor. The difference here is the fabric type switch modifies the length of the wash and spin cycles in addition to the water temps. For example, Heavy/white cottons/towels would agitate for a full 14 minutes with a final spin of 6 minutes. Colors/Normal would agitate for 5 minutes, soak 4 minutes, agitate for 5 minutes and then have a final 6 minute spin. Permanent Press would agitate for 5 minutes, soak 4 minutes, agitate for 5 minutes and have a 2 minute final spin. There would also be a cold cool down spray that would begin when the pressure switch resets and the whole spin sequence would be shortened as a whole. Delicate would agitate for 1 minute, soak 5 minutes, agitate 2 minutes, soak 5 minutes and then agitate 1 minute, spins shortened, final spin would be 3 minutes.

The best way I can describe this model as a rip off of the Maytag A407.

Third model has a 3 speed motor with a 4 pole winding, a 6 pole winding and a third 8 pole winding. 1650 rpm / 1075 rpm / 800 rpm ; fast, medium, low. Cycle times are the same, the only difference is the fabric switch alters the motor speeds. For example, Heavy Duty would be fast/fast the entire cycle. Normal would use some fast and some medium agitation and all spins would be high. Permanent press would use some high some medium agitation but all spins would be medium speed. Knits and Delicate would agitate only at medium speed and spin only at medium speed. Handwash would agitate only at low speed and spin for 2 minutes at medium speed at the start of drain then switch to slow speed spinning. Permanent press does a cold spray at the moment the pressure switch resets. I can't imagine a half a tub drain being relevant to modern fabrics possessing a permanent press label.

The reason for the different makes is that it gives users to option of having a simpler model with less that can go wrong for their needs, ie if a user does not need hand-wash they can buy a the first model machine that lets them save energy on their cottons while being well rinsed and comfortable to handle with a hang dry cycle.

The programmed cycle concept lets users push buttons based on the fabric type and soil rather than having to translate to temps, time, speed, ect.

Finally, all programed cycle washers I have in mind technically have only a single cycle timer. Even those with a prewash option. There are no 5 or more separate cycles doing what the programmed buttons do. That means fewer increments or faster rotation time on the timer, with more or all 7.5 degree increments on incremental advance timers. There is less to go wrong, and less chance of the timer stall out / contacts not making.