Of Course!

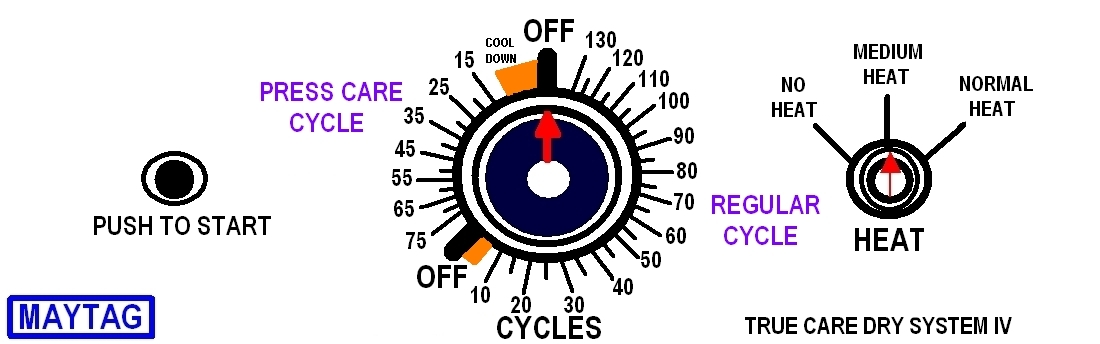

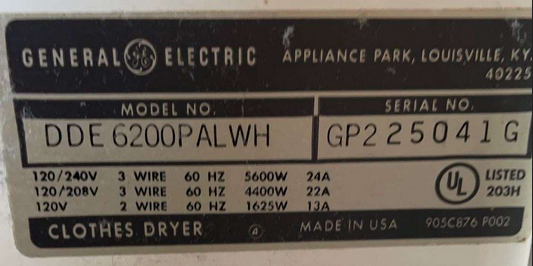

Absolutely. Older dryer were designed and listed for 120 volt adaptation if 240 volts was not available. That is indeed the reason why 90 minute timed dryer cycles had an extra 40+ minutes added to them.

However, that doesn't change the fact full size dryers of the past not intended for 120 volt operation still offered a 90 or 100 minute timed dry cycle. Without switching to low heat mid-way through. And without a 10+ minute cool down. Because 70 minutes of soft heat permanent press treatment was not enough. I highly doubt any customer would consciously refuse to buy a dryer because it offered 90 minutes of unadulterated timed dry.

Shoes work well with towels and even tennis balls thrown in. Shoes can be dried on a rack that goes inside the dryer, as offered by Kenmore back in the day. Nothing gets damaged or worn out.

Burners- of course they are more powerful than ever. Until silly UL mandated burner thermostats which prevent people from being able to cook. A very small percentage of people whom were being negligent started grease fires, so the solution was adding thermostats that cutout the burner.

They work so well, that people are actively bypassing them:

https://www.ncgunowners.com/xf/threads/i-got-a-new-stove.79571/

Read the Youtube reviews if you want an accurate, real world account of what people are experiencing with sensi temp burners:

I've been cooking myself for over 30 years including weekly frying, even when sick or exhausted, and I have never had a grease fire let alone left heating oil unattended. Or kept adding heat the few times oil went above its smoke point.

In other words, the majority of people are punished for the negligent actions of a few. Cost of living increases to cover the cost of new rules which aid or help nobody at the bottom. A concept that goes against freedom, liberty and democracy.

I am a US citizen with inalienable human rights and a consumer.

[this post was last edited: 2/4/2025-09:50]

https://products.geappliances.com/appliance/gea-support-search-content?contentId=37448