You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Photo of Early A806 *NON-PP* Timer Dial?

- Thread starter lowefficiency

- Start date

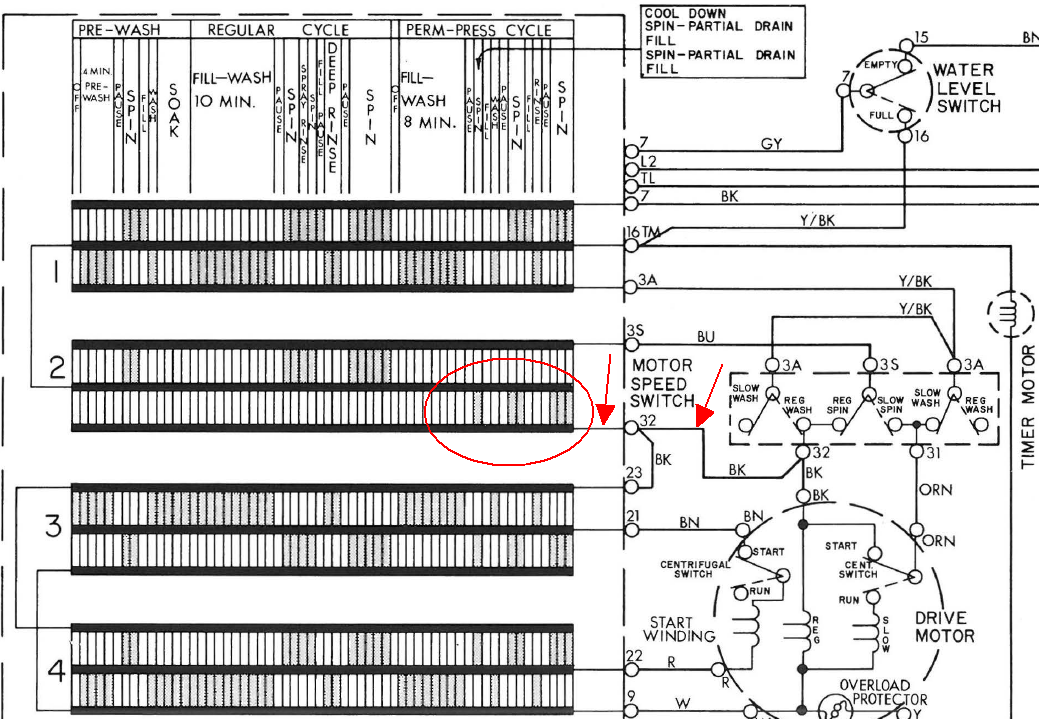

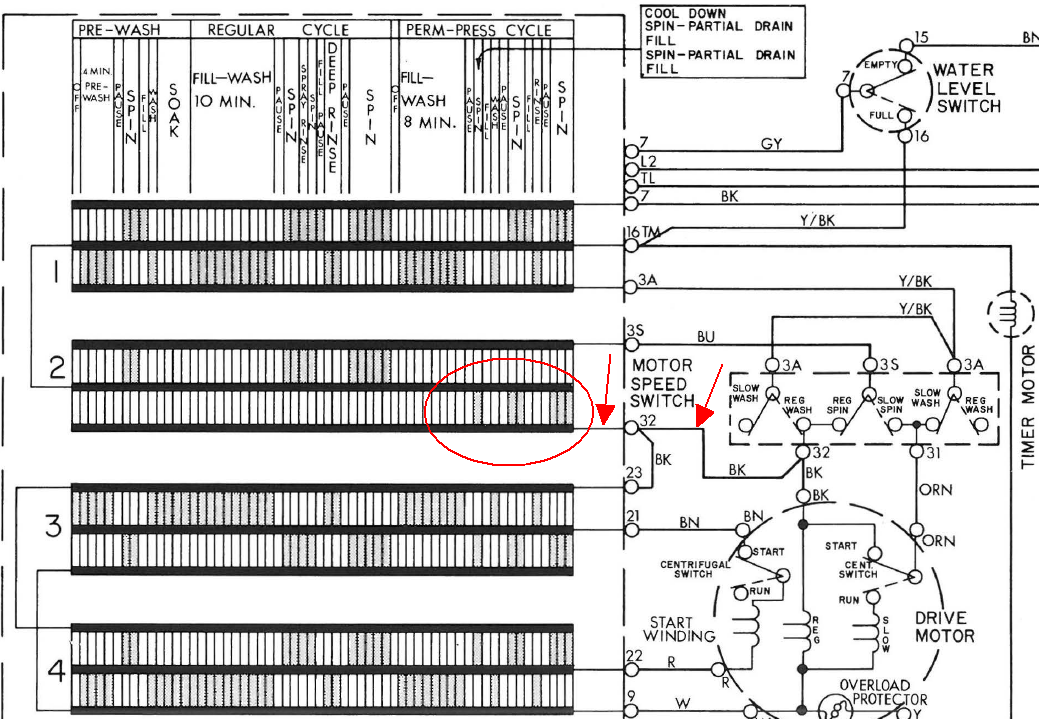

The spin speed is directly controlled by the timer in the permanent press cycle. Contact two upper (3S) sends power to the speed selector switch in the normal cycle, however during the permanent press cool down, post wash permanent press spin and post rinse permanent press spin lower contact (32) sends power directly to the motor's high speed winding.

The times are very short, two and three minutes respectively. My guess is that Maytag didn't/couldn't add extra increments to the timer to account for the lowered speed, and technically they would need to add an over-ride contact anyway to prevent a user from inadvertently washing their wrinkle frees on a long high speed spin, so why not settle on what technically works?

Maytag washers were so gentle in general that IMO a 2 speed motor was just over-kill. Only thing I would have done differently was add a 20 minute+ wash like GE did to account for heavy soils.

The times are very short, two and three minutes respectively. My guess is that Maytag didn't/couldn't add extra increments to the timer to account for the lowered speed, and technically they would need to add an over-ride contact anyway to prevent a user from inadvertently washing their wrinkle frees on a long high speed spin, so why not settle on what technically works?

Maytag washers were so gentle in general that IMO a 2 speed motor was just over-kill. Only thing I would have done differently was add a 20 minute+ wash like GE did to account for heavy soils.

Thanks for the explanations and wiring diagram. Good to know that my machine is working as intended.

I can't imagine that Maytag would remove the ability to choose a slow spin on PP based on any fabric care considerations. Quite the opposite in fact.

I would tend to think along the lines of what Chet said. Perhaps Maytag was concerned that if the user chose a slow spin, it could result in the tub not being fully drained (and fabric softener not being spun out prior to the rinse) in some circumstances or not being sufficiently drained during the cooldown. With no capacity for additional increments or a neutral drain system (with the motor always running at high speed during neutral drain), perhaps they hardwired it for a fast spin to achieve the required drain during the allotted time period. Just my guess anyway.

I can't imagine that Maytag would remove the ability to choose a slow spin on PP based on any fabric care considerations. Quite the opposite in fact.

I would tend to think along the lines of what Chet said. Perhaps Maytag was concerned that if the user chose a slow spin, it could result in the tub not being fully drained (and fabric softener not being spun out prior to the rinse) in some circumstances or not being sufficiently drained during the cooldown. With no capacity for additional increments or a neutral drain system (with the motor always running at high speed during neutral drain), perhaps they hardwired it for a fast spin to achieve the required drain during the allotted time period. Just my guess anyway.

Maytag dependable care washers fast spin on permanent press

Not sure what the thinking was, but it was stupid when every other manufacturer used a slow spin for permanent press, permanent press items were often lined dried as well, so you didn’t need wrinkles pressed into them. I guess I’m surprised they didn’t use a warm rinse on permanent press, lol.

I don’t think Maytag had much in the way of laundry, testing and engineering to make a decision like this. It was like their fabric Matic washers. You take the one washing machine on the market with the most damaging agitation, and then you make a delicate cycle where you go at full speed intermittently. It really doesn’t give the same effect as having a proper low speed motor. They were just saving a few cents by not putting a decent two speed motor in the washer.

But in the end, the high-speed spin didn’t make much difference because most Americans put their stuff in the dryer and it doesn’t make that much difference at the end, and they finally saw the light and changed the agitation because of complaints of clothing damage they knew all along they had problems when I worked for Maytag. They used to talk about it, but never would put it in. Let’s talk service, as they didn’t want any written proof out there that the competitors could use. Because of the agitation damage they went to 10 minute maximum wash periods, we used to get complaints all the time for people that we sold them to that wish they had a 14 or 15 minute wash because the machines didn’t work as well as they’re old Kenmore whirlpool Norge, whatever They had before.

John L

John L

Not sure what the thinking was, but it was stupid when every other manufacturer used a slow spin for permanent press, permanent press items were often lined dried as well, so you didn’t need wrinkles pressed into them. I guess I’m surprised they didn’t use a warm rinse on permanent press, lol.

I don’t think Maytag had much in the way of laundry, testing and engineering to make a decision like this. It was like their fabric Matic washers. You take the one washing machine on the market with the most damaging agitation, and then you make a delicate cycle where you go at full speed intermittently. It really doesn’t give the same effect as having a proper low speed motor. They were just saving a few cents by not putting a decent two speed motor in the washer.

But in the end, the high-speed spin didn’t make much difference because most Americans put their stuff in the dryer and it doesn’t make that much difference at the end, and they finally saw the light and changed the agitation because of complaints of clothing damage they knew all along they had problems when I worked for Maytag. They used to talk about it, but never would put it in. Let’s talk service, as they didn’t want any written proof out there that the competitors could use. Because of the agitation damage they went to 10 minute maximum wash periods, we used to get complaints all the time for people that we sold them to that wish they had a 14 or 15 minute wash because the machines didn’t work as well as they’re old Kenmore whirlpool Norge, whatever They had before.

John L

John L

Not sure what the thinking is

Yet confidently make statements like this "but it was stupid when"

Adding increments to timers requires significant re-engineering of every aspect of the timer. Each new degree requires adding either shorter "dummy" advancements to preserve more complex ones or shortening all the increments in general which greatly increases the probability of miscoordination, not catching, ect while effecting high current break and making. Stall out, contact burn ups, motor burn outs, ect all drastically increase in probably of occurring the further you go from a simple 7.5 degree 48 increment timer. Think of Speed Queens AWN542 as one example.

Less is more.

Maytag agitators and wash action was not the roughest, far from it. They made the best delicate fabric and casuals washer ever conceived. Key was in not overloading. The 1 speed motor concept worked very well, as did the shortened PP spin cycle.

Stop ripping on these beautiful, beautiful washers that gave the best fabric care in the world decade after decade. Sorry that you can't come to terms with Whirlpool losing in those categories.

Yet confidently make statements like this "but it was stupid when"

Adding increments to timers requires significant re-engineering of every aspect of the timer. Each new degree requires adding either shorter "dummy" advancements to preserve more complex ones or shortening all the increments in general which greatly increases the probability of miscoordination, not catching, ect while effecting high current break and making. Stall out, contact burn ups, motor burn outs, ect all drastically increase in probably of occurring the further you go from a simple 7.5 degree 48 increment timer. Think of Speed Queens AWN542 as one example.

Less is more.

Maytag agitators and wash action was not the roughest, far from it. They made the best delicate fabric and casuals washer ever conceived. Key was in not overloading. The 1 speed motor concept worked very well, as did the shortened PP spin cycle.

Stop ripping on these beautiful, beautiful washers that gave the best fabric care in the world decade after decade. Sorry that you can't come to terms with Whirlpool losing in those categories.

I posted at least once in the past, maybe a couple times, about a long-time family friend who told me about having bought a Maytag ("I needed a new washer and decided I'm gonna get a Maytag") and returned it because it twisted and mangled her knit tops and sweaters. Previous washers that I recall were a mid 60s GE FilterFlo and a 1970s Whirlpool. She had a Frigidaire frontloader pair the last time I saw her before she moved to Bowie/Nocona area.

Anyone who has anything damaged in a Maytag either didn’t load the machine properly or use the correct cycles, or simply were too cheap to buy a Maytag 806 with every cycle imaginable. I almost always use the gentle wash with a fast spin combination for lightly soiled items and smaller loads on my Maytag 806, never had anything damaged or show signs of excessive wear. Been using Maytags for 9 years and never had anything damaged, many others have been using Maytags for decades as well and never had anything damaged.

Sean, weren't Maytags of the 70s and 80s the gentlest washers ever made?

I think the issues people had is overloading. Maytags if loaded forcibly enough would bog down the motor or stall out completely. Some would call this a design flaw, I call this aggressive mis-use.

My honest opinion is that if Maytag included a longer wash time customer satisfaction would have increased.

In fact I'd go on a limb and say a gentler, yet longer wash time is better in a top load washer. It lets detergent dissolve, it lets enzymes work and it loosens heavy soil. I have for a while now envisioned heavy/normal/delicate being built into the dial with washes and soaks.

I think the issues people had is overloading. Maytags if loaded forcibly enough would bog down the motor or stall out completely. Some would call this a design flaw, I call this aggressive mis-use.

My honest opinion is that if Maytag included a longer wash time customer satisfaction would have increased.

In fact I'd go on a limb and say a gentler, yet longer wash time is better in a top load washer. It lets detergent dissolve, it lets enzymes work and it loosens heavy soil. I have for a while now envisioned heavy/normal/delicate being built into the dial with washes and soaks.

Maytags in general are gentle, but the chumps who were stuck in their ways along with being cheap ‘n ignorant are the reason why Maytag got a bad wrap.

They say the customer is always right and in many ways that’s true, but when you refuse to listen to the instructions in the owner’s manual and in general don’t use common sense will lead to some problems.

They say the customer is always right and in many ways that’s true, but when you refuse to listen to the instructions in the owner’s manual and in general don’t use common sense will lead to some problems.

Of course. But I will admit that I think what pushed people away from Maytag was not having enough wash time on the dial. GE included up to 20 minutes of wash time which definitely helps with heavier soils. I think 14 or 16 minutes of agitation for normal might have worked better in a Maytag, 24 for heavy soils.

Stain Scrubber System

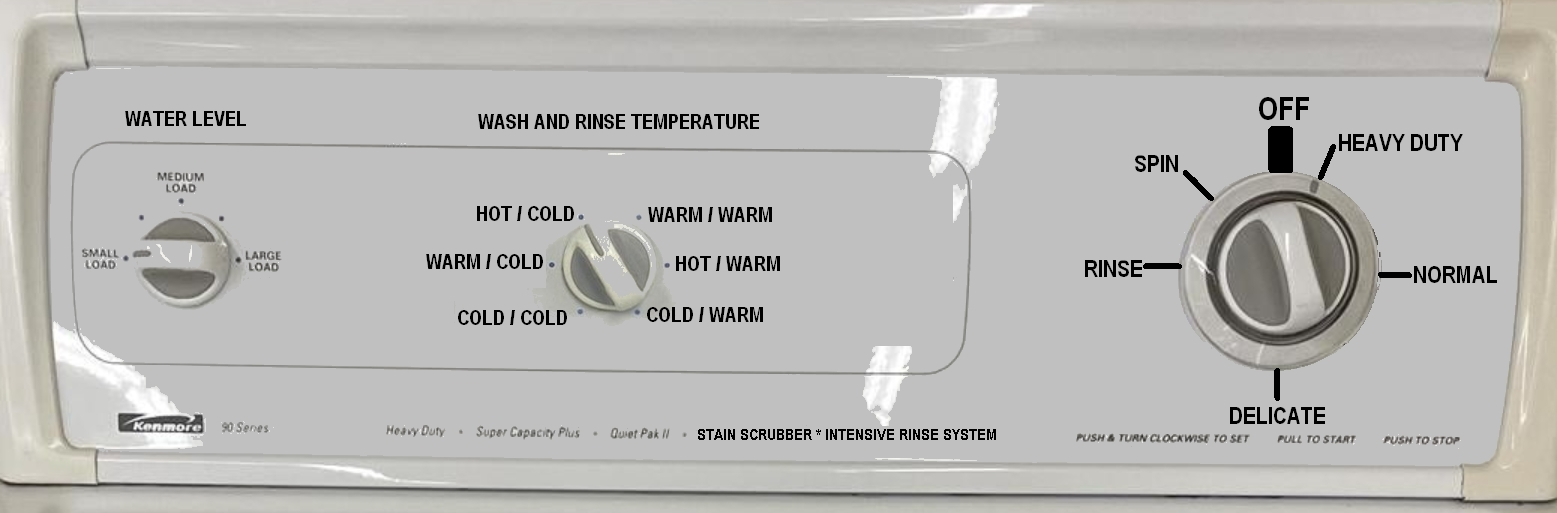

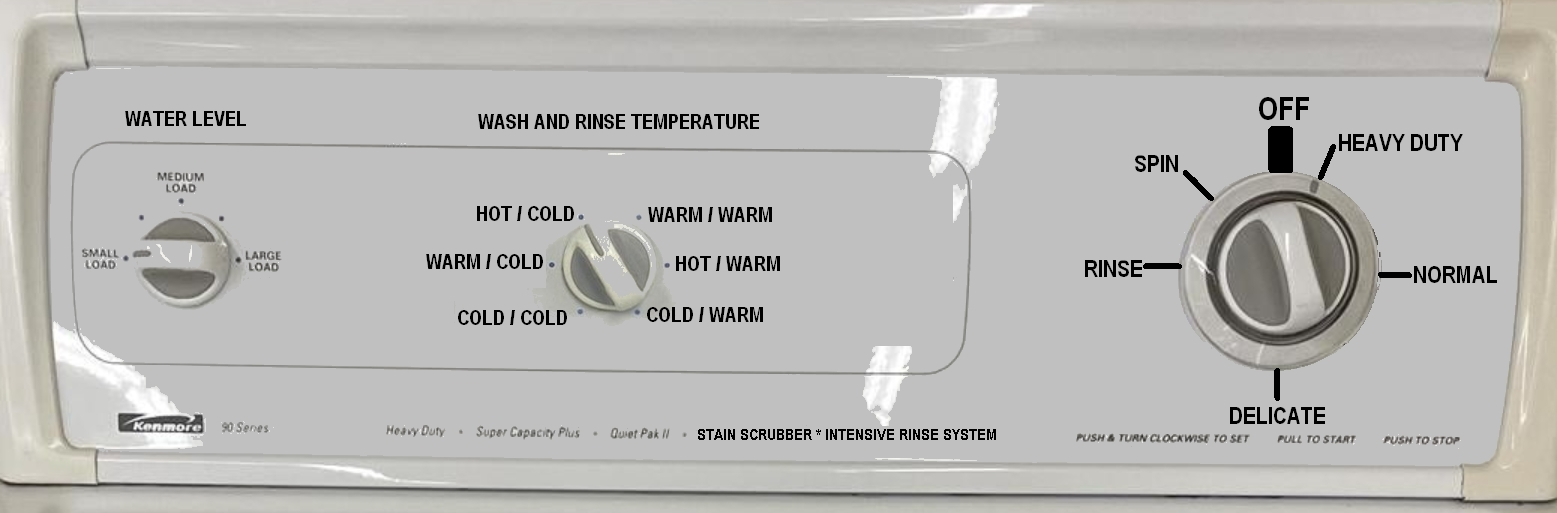

This how I imagine a potential modern 2025 iteration of the Maytag helical dependable care washer with straight vane agitator with no explicit permanent press cycle on the dial. The washer would use a series of soaks and longer total agitation time which would aid in cleaning, compensating for the gentle wash action with normal and heavy soiled garments while boosting stain removal. This washer would be great for families, particularly with all the staining that occurs in sports, playing, cooking, eating, ect.

Normal wash time is 44 minutes, but still more tolerable than many newer washers. Essentially a washer with a built in auto soak cycle for normal and heavy duty fabrics, an inspiration of the Maytag A407. A Permanent Press Cool Down is built into all cycles.

66 minute continuous advance timer, 360 degrees per full timer revolution, Singer Timer Design Iteration; Cycle sequence as follows:

1 minute lead in buffer

1 minute fill - this is also technically a buffer interval to positively engage the associated wash fill contacts.

6 minute fill -Start point of Heavy Duty Cycle-

Agitate 8 minutes

Fill and soak 2 minutes

Fill and soak 6 minutes -Start point of Normal Cycle-

Agitate 8 minutes

Fill and soak 2 minutes

Fill and soak 6 minutes -Start of Delicate Cycle-

Agitate 8 minutes

Pause 1 minute

Spin 2 minutes

Spin Spray Cold Only 1 minute --Permanent Press Cool Down-- Occurs in all cycles and settings

Spin 2 minutes

Spin Spray selected rinse temp 1 minute

Spin 2 minutes

Spin Spray selected rinse temp 1 minute

Spin 5 minutes

1 minute lead out buffer

2 minutes OFF timer

[this post was last edited: 4/9/2025-00:11]

This how I imagine a potential modern 2025 iteration of the Maytag helical dependable care washer with straight vane agitator with no explicit permanent press cycle on the dial. The washer would use a series of soaks and longer total agitation time which would aid in cleaning, compensating for the gentle wash action with normal and heavy soiled garments while boosting stain removal. This washer would be great for families, particularly with all the staining that occurs in sports, playing, cooking, eating, ect.

Normal wash time is 44 minutes, but still more tolerable than many newer washers. Essentially a washer with a built in auto soak cycle for normal and heavy duty fabrics, an inspiration of the Maytag A407. A Permanent Press Cool Down is built into all cycles.

66 minute continuous advance timer, 360 degrees per full timer revolution, Singer Timer Design Iteration; Cycle sequence as follows:

1 minute lead in buffer

1 minute fill - this is also technically a buffer interval to positively engage the associated wash fill contacts.

6 minute fill -Start point of Heavy Duty Cycle-

Agitate 8 minutes

Fill and soak 2 minutes

Fill and soak 6 minutes -Start point of Normal Cycle-

Agitate 8 minutes

Fill and soak 2 minutes

Fill and soak 6 minutes -Start of Delicate Cycle-

Agitate 8 minutes

Pause 1 minute

Spin 2 minutes

Spin Spray Cold Only 1 minute --Permanent Press Cool Down-- Occurs in all cycles and settings

Spin 2 minutes

Spin Spray selected rinse temp 1 minute

Spin 2 minutes

Spin Spray selected rinse temp 1 minute

Spin 5 minutes

1 minute lead out buffer

2 minutes OFF timer

[this post was last edited: 4/9/2025-00:11]

Similar threads

- Replies

- 4

- Views

- 143

- Replies

- 9

- Views

- 260

- Replies

- 3

- Views

- 86

Latest posts

-

-

How long is too long to dry in a domestic dryer

- Latest: adam-aussie-vac

-

-