You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Why Did Older Dishwasher Have Such Enormous Motors?

- Thread starter Chetlaham

- Start date

This dishwasher uses 13.2 gallons?

My KDS-18 uses 16 gallons and it doesn't bother me in the least, especially when compared to running 45-47-ish gallons PER load in my 806 with it's modified spray rinse cycle.

Vintage water hogging dishwasher, vintage 4-5 gallon toilets, and vintage top loaders. Ya know what my water bill averages per month? $25-$30.

My KDS-18 uses 16 gallons and it doesn't bother me in the least, especially when compared to running 45-47-ish gallons PER load in my 806 with it's modified spray rinse cycle.

Vintage water hogging dishwasher, vintage 4-5 gallon toilets, and vintage top loaders. Ya know what my water bill averages per month? $25-$30.

13.2 Gallons

@johnb300m- Please I politely ask you to stop with the negativity. Post #29 adds nothing of value to the discussion.

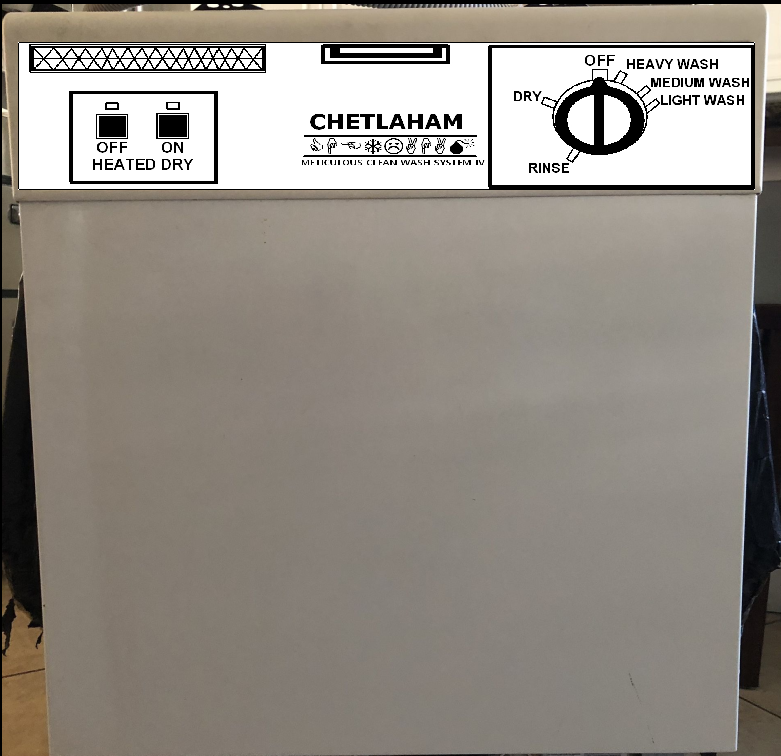

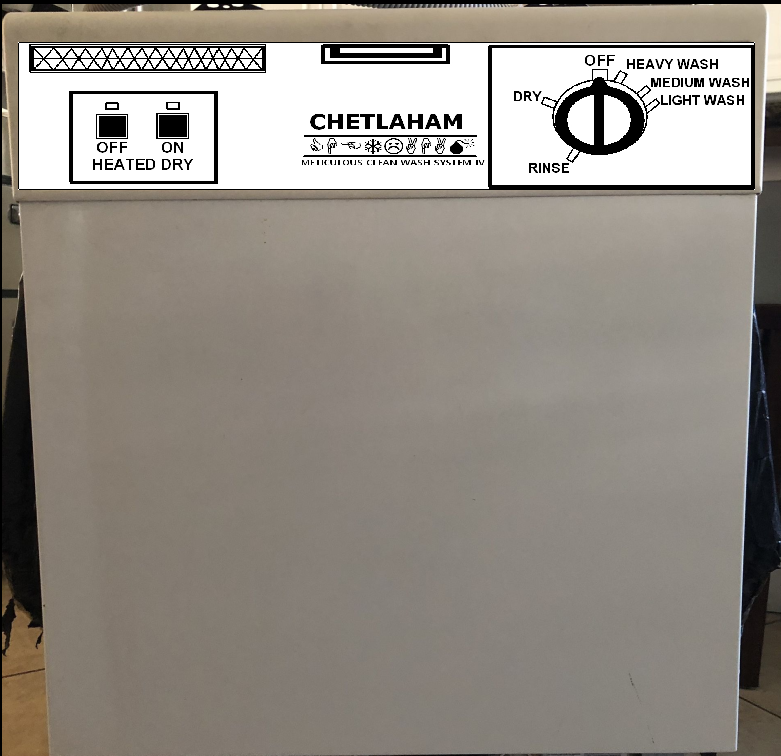

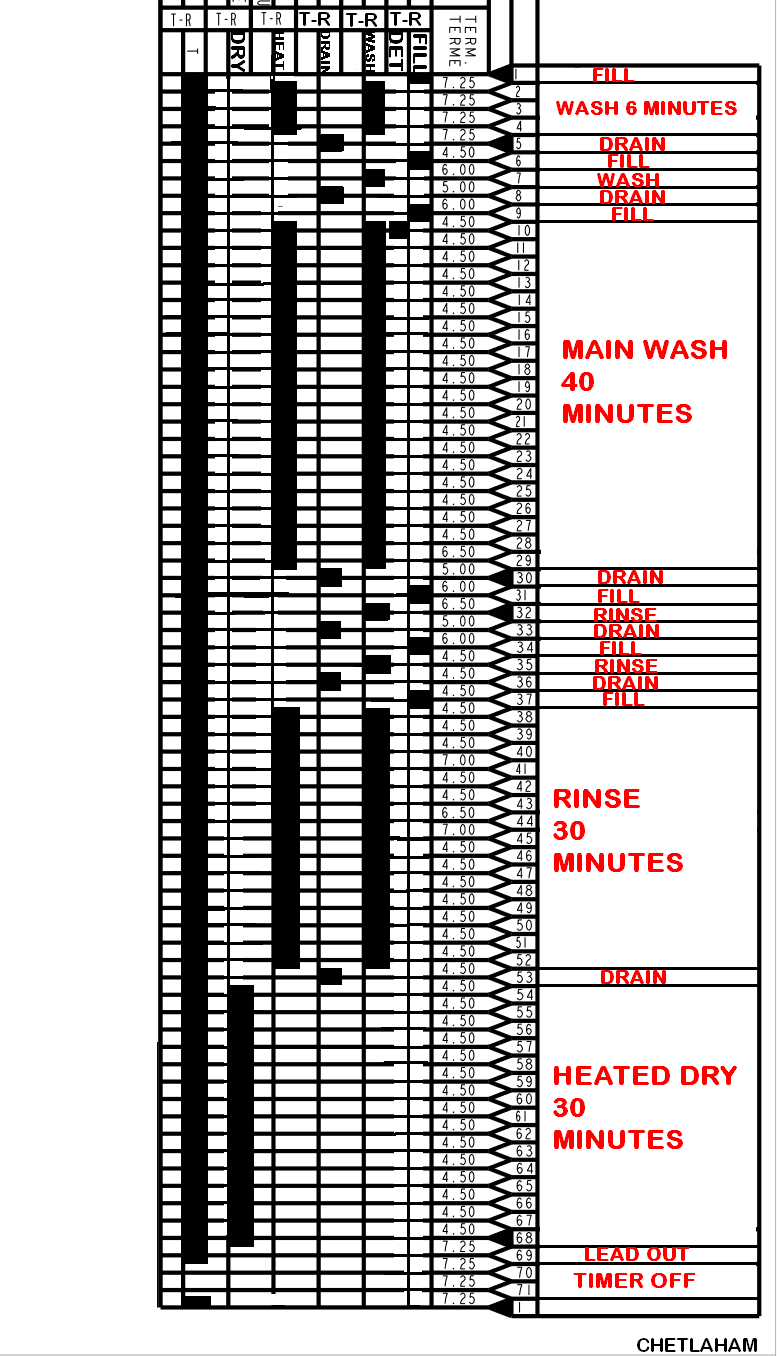

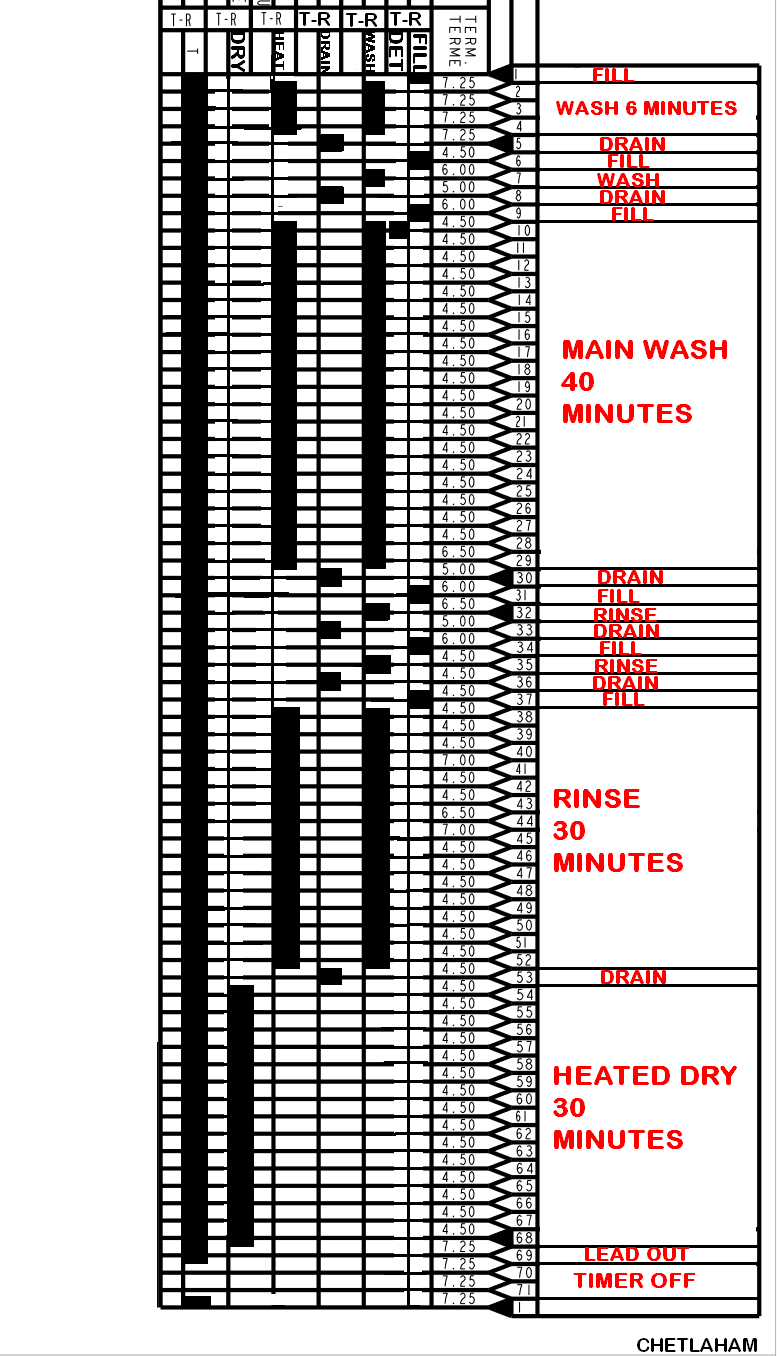

Anyway, yes, the Heavy wash on this dishwasher does indeed use 13.2 gallons of water per cycle. The timer can be started in 3 places:

Heavy- 13.2 Gallons

Medium - 11 Gallons

Light - 8.8 Gallons

None of these cycles waste water or electricity- on the contrary they save order of magnitude more water and electricty as there is no need to manually pre-rinse, prewash, soak, scrub, use the rinse and hold cycle, afresh cycle or the need to clean the machines filter. All that is taken and done by the machine.

The water ussage here is the ideal amount needed to realistically clean dishware unlike the DOE energy cycle which only takes water and energy usage at face value without evaluating actual performance short and long term. There is even an extra fill and drain in the rinse cycle to let the user generously dose on detergent worry free (if needed) and to aid in soil carry away post main wash. Dishes in this machine actually go in untouched besides scrapping. Water should never touch used plates until they are actually in the dishwasher.

@johnb300m- Please I politely ask you to stop with the negativity. Post #29 adds nothing of value to the discussion.

Anyway, yes, the Heavy wash on this dishwasher does indeed use 13.2 gallons of water per cycle. The timer can be started in 3 places:

Heavy- 13.2 Gallons

Medium - 11 Gallons

Light - 8.8 Gallons

None of these cycles waste water or electricity- on the contrary they save order of magnitude more water and electricty as there is no need to manually pre-rinse, prewash, soak, scrub, use the rinse and hold cycle, afresh cycle or the need to clean the machines filter. All that is taken and done by the machine.

The water ussage here is the ideal amount needed to realistically clean dishware unlike the DOE energy cycle which only takes water and energy usage at face value without evaluating actual performance short and long term. There is even an extra fill and drain in the rinse cycle to let the user generously dose on detergent worry free (if needed) and to aid in soil carry away post main wash. Dishes in this machine actually go in untouched besides scrapping. Water should never touch used plates until they are actually in the dishwasher.

Adding nothing to the discussion lol

Chet and Jerome You are in the classic Appliance thread where we talk about vintage appliances and problems. Everything you two guys have posted is just make believe it has nothing to do with anything.

U2 can talk among yourselves on the message board etc

This is not an attack on you guys personally, but the site is not intended for make-believe drawings, these things can go in the super forum if you’d like I suppose, but label it as make believe don’t try to act like this is a serious discussion, please

John

Chet and Jerome You are in the classic Appliance thread where we talk about vintage appliances and problems. Everything you two guys have posted is just make believe it has nothing to do with anything.

U2 can talk among yourselves on the message board etc

This is not an attack on you guys personally, but the site is not intended for make-believe drawings, these things can go in the super forum if you’d like I suppose, but label it as make believe don’t try to act like this is a serious discussion, please

John

@ John- cite the forum rules stating personally made or fair use drawings, pictures, re-productions, schematics, cycles, or modifications pertaining to vintage appliances shall not be posted or discussed on AW.org.

@johnb300m:

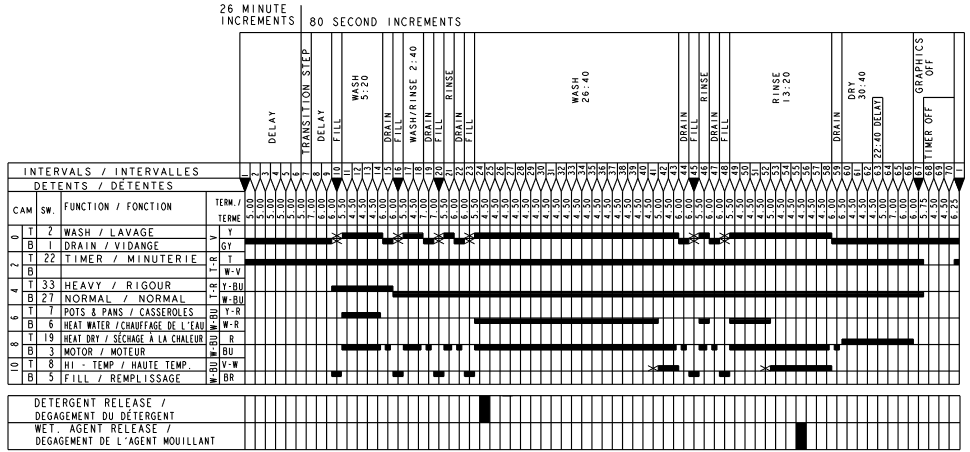

I've got 3 BOL cycle sequences that use only 8.8 gallons of water- however unless you pre-rinse your dishes well I highly doubt you'd want to use any of these three cycles or have the same water going around for 30+ minutes even though you would probably still get good results with the Power Clean Filter Module. IMO you need extra water for pre-washing and pre-rinsing excessive soils associated with dishware that has not been pre-rinsed.

Variant one, long heated rinse for best drying-

Variant two, shortened rinse-

Variant three, long main wash for baked on soils, no time given for building thermal inertia in the rinse, heated dry increased by 6 minutes to compensate-

Jerome let me know what you think and what you approve of.

@johnb300m:

I've got 3 BOL cycle sequences that use only 8.8 gallons of water- however unless you pre-rinse your dishes well I highly doubt you'd want to use any of these three cycles or have the same water going around for 30+ minutes even though you would probably still get good results with the Power Clean Filter Module. IMO you need extra water for pre-washing and pre-rinsing excessive soils associated with dishware that has not been pre-rinsed.

Variant one, long heated rinse for best drying-

Variant two, shortened rinse-

Variant three, long main wash for baked on soils, no time given for building thermal inertia in the rinse, heated dry increased by 6 minutes to compensate-

Jerome let me know what you think and what you approve of.

to chetlaham

I like them all.

I like them all.

I worked hard on them, even had to do the math. My head hurts LOL. I'm glad you like and approve of them, that means a lot to me.

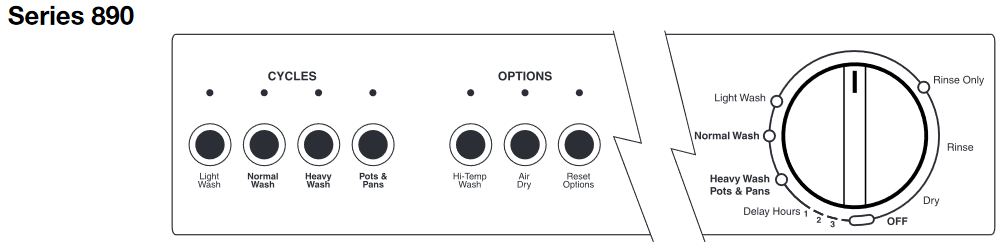

I think one of the best things would be getting rid of the thermal hold for a fixed period of heated time in both the prewash, mainwash and final rinse. This lets the water temps exceed 140*F, giving that true Potscrubber performance. It also increases reliability as I've read online threads where Power Clean timers would fail by stalling out at the thermal hold and not advance even when temperatures were satisfied. Ditching all the thermal hold wiring and switching to an energy efficient low vibration permanent split capacitor motor frees up contacts in both the 6 and 8 contact row timers for things like various indicator lights and staggered timed heat. A cycling contact can provide intermittent heat for China washes while a long duration close contact can provide Pot and Pans heating as similarly done with high end dura-wash dishwashers to achieve normal vs hi-temp options. Much less to go wrong.

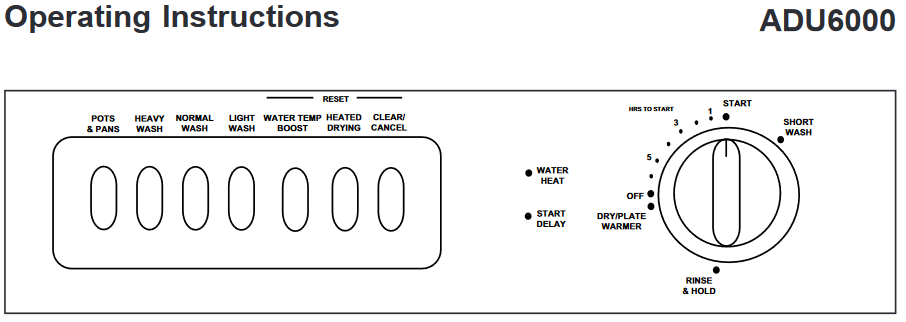

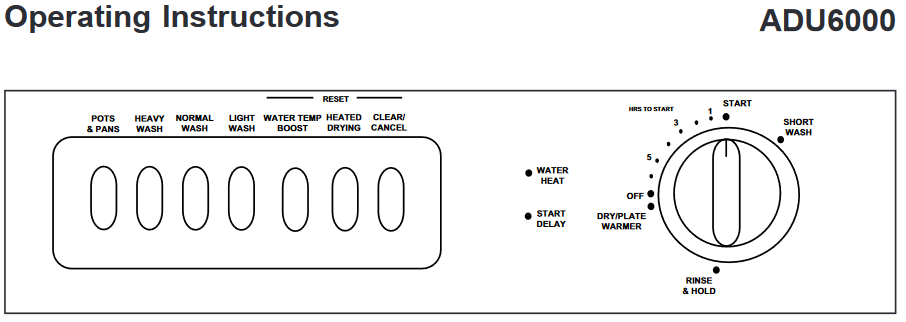

Option buttons will control heat, knob will control the number fills for MOL and up models.

I think one of the best things would be getting rid of the thermal hold for a fixed period of heated time in both the prewash, mainwash and final rinse. This lets the water temps exceed 140*F, giving that true Potscrubber performance. It also increases reliability as I've read online threads where Power Clean timers would fail by stalling out at the thermal hold and not advance even when temperatures were satisfied. Ditching all the thermal hold wiring and switching to an energy efficient low vibration permanent split capacitor motor frees up contacts in both the 6 and 8 contact row timers for things like various indicator lights and staggered timed heat. A cycling contact can provide intermittent heat for China washes while a long duration close contact can provide Pot and Pans heating as similarly done with high end dura-wash dishwashers to achieve normal vs hi-temp options. Much less to go wrong.

Option buttons will control heat, knob will control the number fills for MOL and up models.

Eh, thermal hold is a great idea, just make the components more robust so they don't fail as easy. I'm assuming it's the contacts that fail from being burned/pitted.

Thermal hold to 150F for wash cycles, final sani rinse 180F. That should be hardwired in and not de-selectable. A 180F final rinse eliminates the need for heated dry. Pop the door open after draining in the final rinse water and flash dry.

Thermal hold to 150F for wash cycles, final sani rinse 180F. That should be hardwired in and not de-selectable. A 180F final rinse eliminates the need for heated dry. Pop the door open after draining in the final rinse water and flash dry.

Alright Dan, now you've done it. 30 minute heated rinse! I'm still including a dry, I like my dishware baked!

The thing is water coming already hot (+145*F) will trigger a short main wash (12 minutes) when the time needed to scour dish and bake-ware (30-40 minutes) would provide ample time to heat the water as it is.

I feel like thermal holds were a way of the past by not penalizing users who had hot water. Those with 150*F tanks could still enjoy normal cycle times or at least normal for that period of time.

A 150*F thermal hold followed by a 180*F thermal would require two thermostats, or one stat with a bias heater further complicating things. Robustness is a key ingredient in any appliance, however simplicity will always take it to the next level eliminating at least one more thing that can go wrong when millions of machines are in use. Small 0.001% problems become problems on a grand scale. Also ff something does go wrong (like the heater giving out) there is no fail safe as the machine will run indefinitely until manually stopped. Personally I really don't like the concept of breaking busses in the timer, re-feeding, extraneous switching or stalling the timer based on external inputs.

I've always like GE's approach. They moved away from temperature sensing based water heating on their EM models and built the time into the main wash and rinse cycles. I like the idea of the timer being absolute, at the top running above all else switched across the line by a single contact having the final say in any cycle sequence.

[this post was last edited: 8/20/2024-06:46]

The thing is water coming already hot (+145*F) will trigger a short main wash (12 minutes) when the time needed to scour dish and bake-ware (30-40 minutes) would provide ample time to heat the water as it is.

I feel like thermal holds were a way of the past by not penalizing users who had hot water. Those with 150*F tanks could still enjoy normal cycle times or at least normal for that period of time.

A 150*F thermal hold followed by a 180*F thermal would require two thermostats, or one stat with a bias heater further complicating things. Robustness is a key ingredient in any appliance, however simplicity will always take it to the next level eliminating at least one more thing that can go wrong when millions of machines are in use. Small 0.001% problems become problems on a grand scale. Also ff something does go wrong (like the heater giving out) there is no fail safe as the machine will run indefinitely until manually stopped. Personally I really don't like the concept of breaking busses in the timer, re-feeding, extraneous switching or stalling the timer based on external inputs.

I've always like GE's approach. They moved away from temperature sensing based water heating on their EM models and built the time into the main wash and rinse cycles. I like the idea of the timer being absolute, at the top running above all else switched across the line by a single contact having the final say in any cycle sequence.

[this post was last edited: 8/20/2024-06:46]

GE's Water Heating

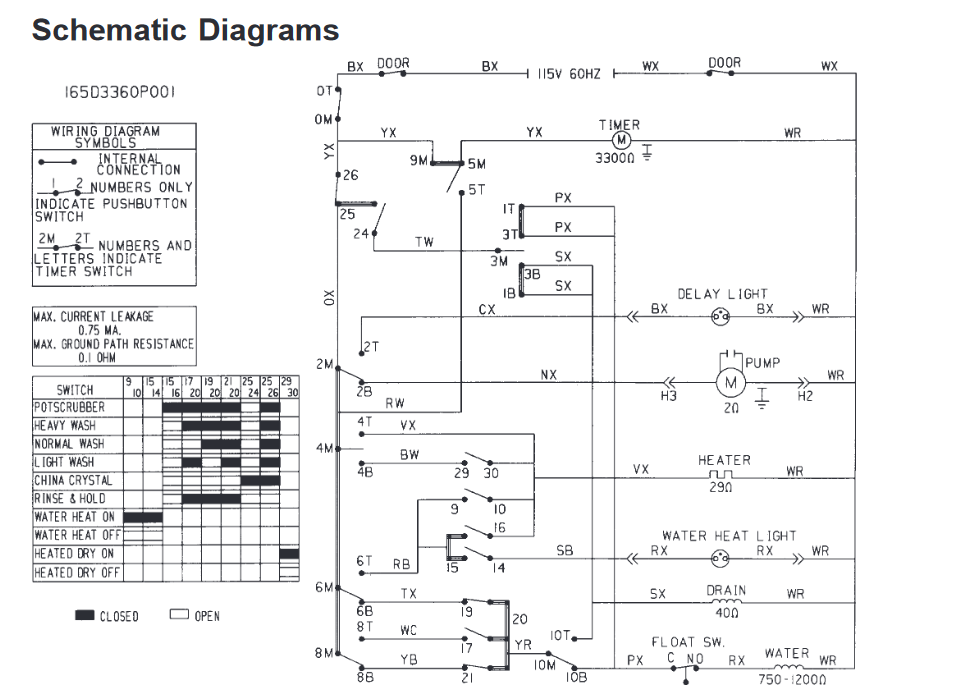

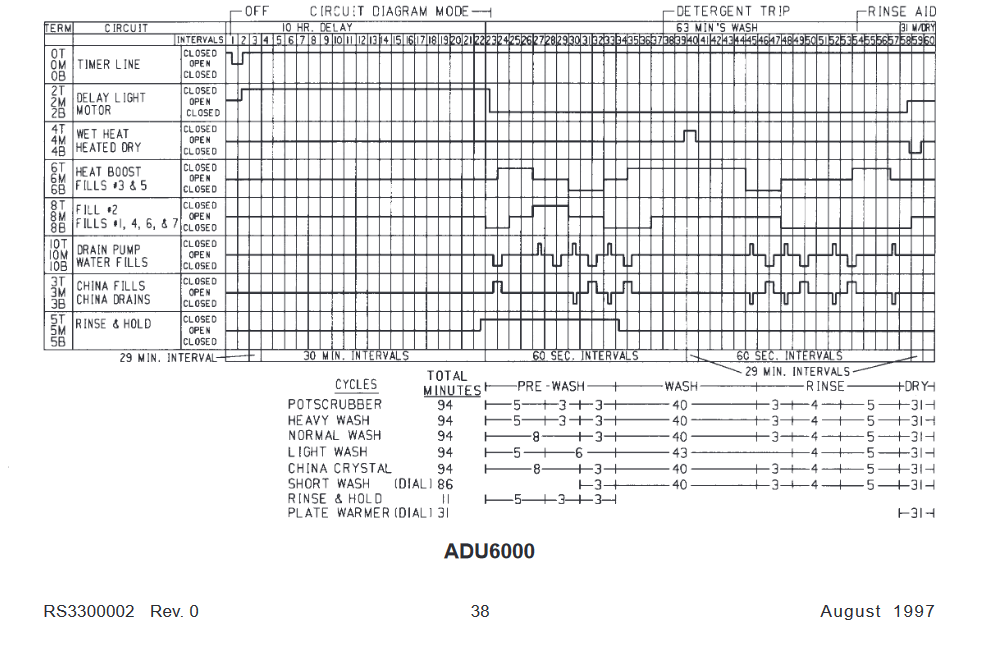

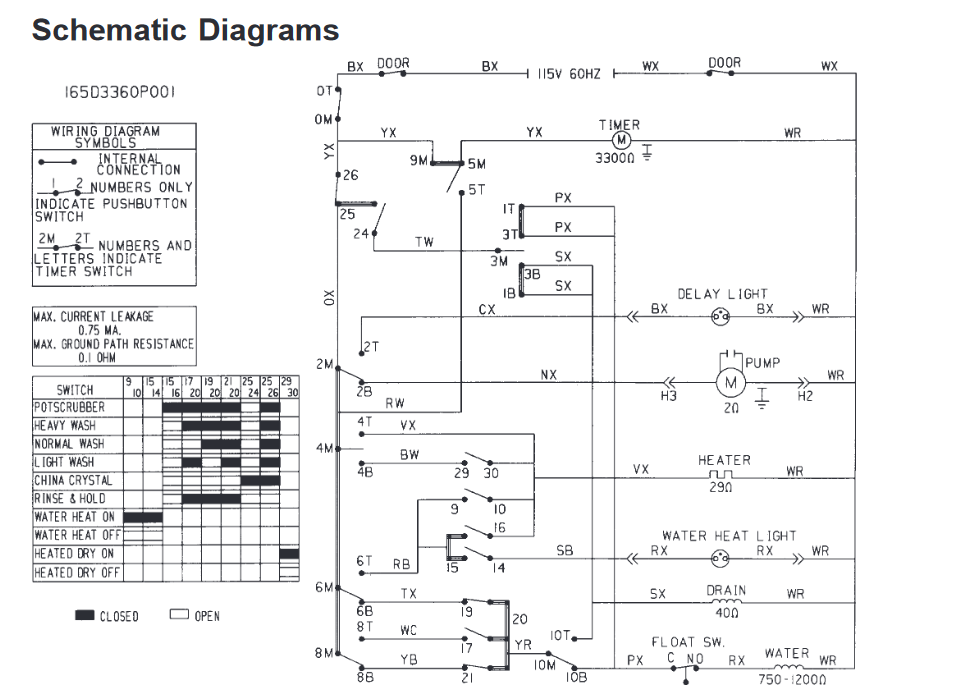

I like GE's latter model Potscrubber water heating system the best. The timer runs continually through out the entire cycle, being at the top of the circuit switched by only one master timer contact (0M-0T) that does not open until the timer advance out of the dry period. Where a thermal hold would normally be present, GE uses a 29 minute delayed timer increment with a dedicated "Wet Heat" 4M-4T water heating contact. This contact is hard wired and can not be over-ridden, mimicking a forced thermal hold. If extra heat is desired to obtain water hotter than normal, achievable by selecting "Potscrubber" or "Water Heat", 10 minutes of heat is added around the delayed increment, in the first pre wash and in the final rinse for a true high temp wash experience. Depressing "Water Heat" closes push-button contacts 9-10 and 14-15 connecting the water heat light and supplementary 6M-6T "Heat Boost" contact to the heating element circuit. This illuminates the water heat light every time the heating element is energized letting the user know tub water is being heated much the same way some Whirlpool dishwashers illuminated a heating delay light when doing a thermal hold.

In any case all cycles have a long 40 or 43 minute main wash regardless of the incoming water temperature. Heating temperatures and cycles are achieved by the amount of time the heater is engaged in the cycle rather than the amount of time the timer is stalled. Just my preference.

TOL Dura wash machines use a similar concept.

As an example a TOL GE built Amana:

I like GE's latter model Potscrubber water heating system the best. The timer runs continually through out the entire cycle, being at the top of the circuit switched by only one master timer contact (0M-0T) that does not open until the timer advance out of the dry period. Where a thermal hold would normally be present, GE uses a 29 minute delayed timer increment with a dedicated "Wet Heat" 4M-4T water heating contact. This contact is hard wired and can not be over-ridden, mimicking a forced thermal hold. If extra heat is desired to obtain water hotter than normal, achievable by selecting "Potscrubber" or "Water Heat", 10 minutes of heat is added around the delayed increment, in the first pre wash and in the final rinse for a true high temp wash experience. Depressing "Water Heat" closes push-button contacts 9-10 and 14-15 connecting the water heat light and supplementary 6M-6T "Heat Boost" contact to the heating element circuit. This illuminates the water heat light every time the heating element is energized letting the user know tub water is being heated much the same way some Whirlpool dishwashers illuminated a heating delay light when doing a thermal hold.

In any case all cycles have a long 40 or 43 minute main wash regardless of the incoming water temperature. Heating temperatures and cycles are achieved by the amount of time the heater is engaged in the cycle rather than the amount of time the timer is stalled. Just my preference.

TOL Dura wash machines use a similar concept.

As an example a TOL GE built Amana:

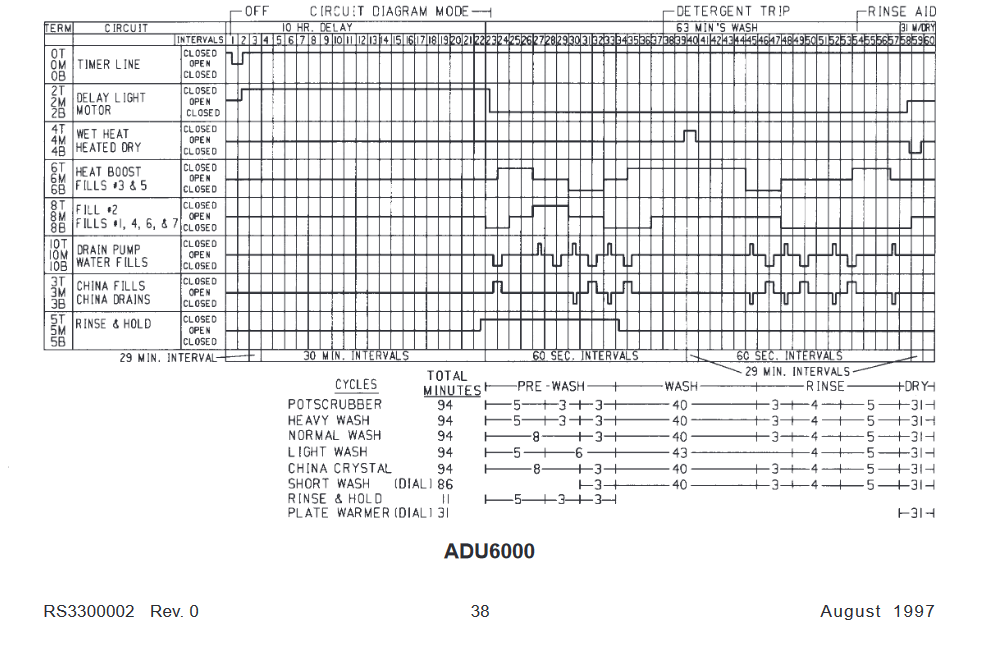

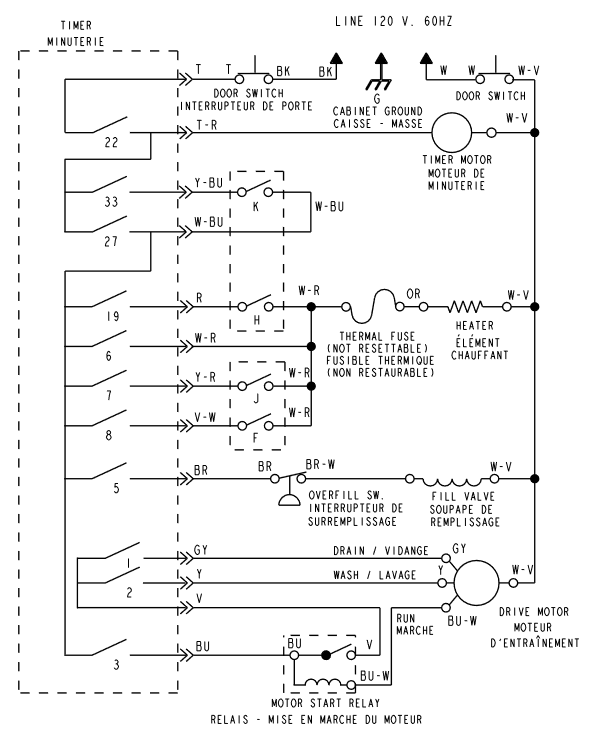

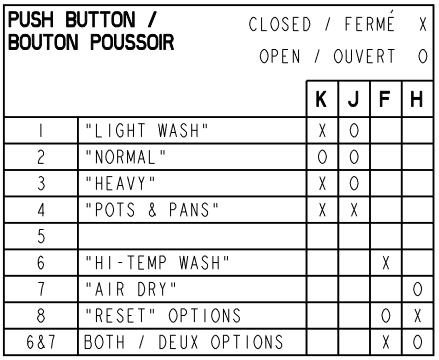

Dura Wash Time Based Heating

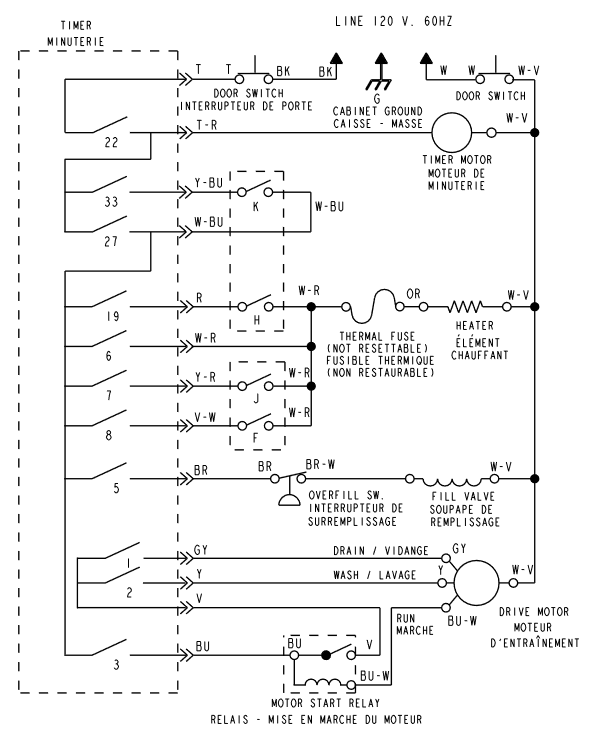

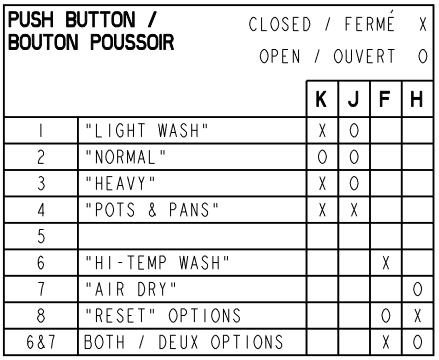

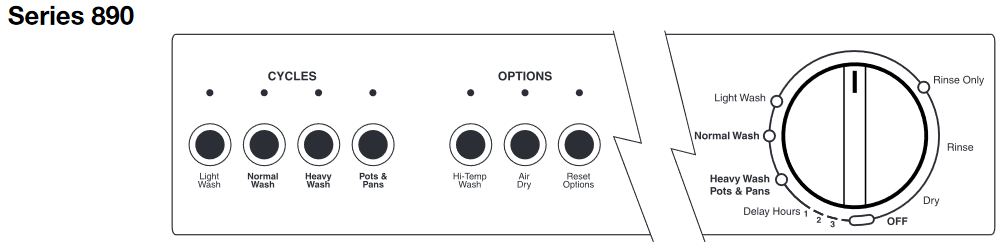

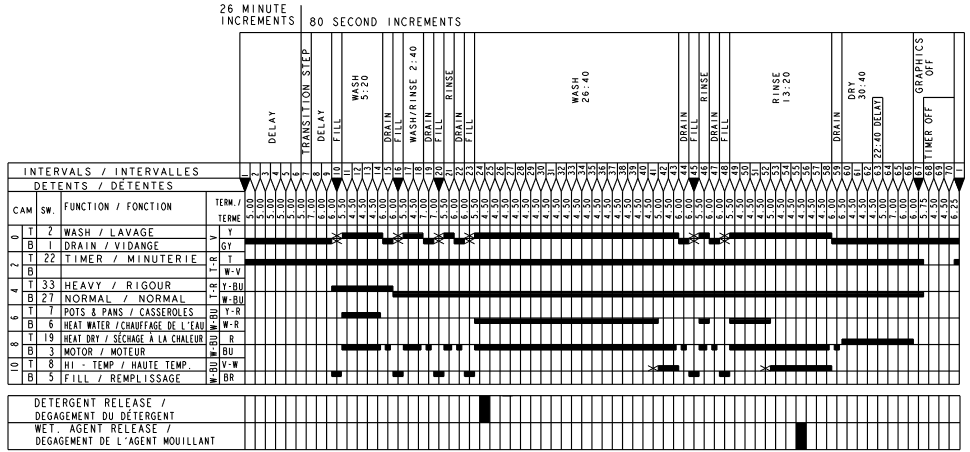

This is another water heating system I really like and I wish was used on the Power Clean Modules. Pots&Pans and Hi-Temp wash is achieved by adding heat at various parts of the cycle. For example, contact 6 provides 24 minutes of mandatory water heating in the main wash, 80 seconds of mandatory watering heat in the first post main wash rinse and 5.3 minutes of mandatory water heating in the final rinse. Depressing Pots & Pans connects timer contact 7 to the heating element circuit providing 5 minutes 20 seconds of water heating through the first pre wash. This heat differentiates the same number of water change outs between being classed as "Pots and Pans" vs "Heavy Wash" Depressing push-button "Hi-Temp Wash" connects timer contact 8 to the heating element circuit providing 2 minutes 40 seconds of water heating in the main wash and 8 minutes of water heating in the final rinse.

Interesting concept I'd like to see stretched. Having the number of water change outs and time dictated by the user selection of the dial, while an array of options like "Pots and Pans" "Heavy" "Normal" "Light" "Low energy" "China Crystal" "Hi-Temp Wash" and "Hi-Temp Rinse" would dictate the amount of heat added to the Prewash, Main Wash and Final Rinse.

This is another water heating system I really like and I wish was used on the Power Clean Modules. Pots&Pans and Hi-Temp wash is achieved by adding heat at various parts of the cycle. For example, contact 6 provides 24 minutes of mandatory water heating in the main wash, 80 seconds of mandatory watering heat in the first post main wash rinse and 5.3 minutes of mandatory water heating in the final rinse. Depressing Pots & Pans connects timer contact 7 to the heating element circuit providing 5 minutes 20 seconds of water heating through the first pre wash. This heat differentiates the same number of water change outs between being classed as "Pots and Pans" vs "Heavy Wash" Depressing push-button "Hi-Temp Wash" connects timer contact 8 to the heating element circuit providing 2 minutes 40 seconds of water heating in the main wash and 8 minutes of water heating in the final rinse.

Interesting concept I'd like to see stretched. Having the number of water change outs and time dictated by the user selection of the dial, while an array of options like "Pots and Pans" "Heavy" "Normal" "Light" "Low energy" "China Crystal" "Hi-Temp Wash" and "Hi-Temp Rinse" would dictate the amount of heat added to the Prewash, Main Wash and Final Rinse.

ragnboneman

Well-known member

I never have prints that tell me much anymore in the industrial electrical equipment I work on.

In the good old days you might spend an afternoon doing a repair and finding a bad contact that held up a sequence..

Now its digital and its much harder to understand what is going on without a computer hooked up....

Lovely lovely prints, tell a story..

In the good old days you might spend an afternoon doing a repair and finding a bad contact that held up a sequence..

Now its digital and its much harder to understand what is going on without a computer hooked up....

Lovely lovely prints, tell a story..

lavamat_jon

Well-known member

13 gallons = 50 litres

That is an awful lot of water, and you won’t see that implemented on any machine nowadays. Whilst fine for us few collectors who admire and run the old machines, for the average person with a modern machine that is just far too much, and such a waste if the whole population collectively uses 5 times as much water to wash their dishes.

Most modern dishwashers in Europe can pre wash, wash, and rinse multiple times using 8-12 litres (approx 2-3 gallons) water and around 1kWH. And guess what - everything comes out to a high standard.

Hell, even some of my 20+ year old vintage washing machines use less than 50 litres to wash an entire load of laundry.

Attached are photos of a burnt on pasta bake dish from the other night, washed on the intensive cycle with just 12l of water, 1.2kWH and 5 water changes.

In this modern age that sort of waste is unacceptable.

That is an awful lot of water, and you won’t see that implemented on any machine nowadays. Whilst fine for us few collectors who admire and run the old machines, for the average person with a modern machine that is just far too much, and such a waste if the whole population collectively uses 5 times as much water to wash their dishes.

Most modern dishwashers in Europe can pre wash, wash, and rinse multiple times using 8-12 litres (approx 2-3 gallons) water and around 1kWH. And guess what - everything comes out to a high standard.

Hell, even some of my 20+ year old vintage washing machines use less than 50 litres to wash an entire load of laundry.

Attached are photos of a burnt on pasta bake dish from the other night, washed on the intensive cycle with just 12l of water, 1.2kWH and 5 water changes.

In this modern age that sort of waste is unacceptable.

@lavamat_jon: What happens to all the food solids in your machine? Is there a macerator? Don't take this the wrong way but I can't picture these UK machines passing a cake test like the Power Cleans could. Or be as easy to service. Or as long lasting.

I do thank you for the backed on pan coming out clean. That does sway my opinion in favor of your machine- you have proved that your machine is capable of scrubbing.

I do thank you for the backed on pan coming out clean. That does sway my opinion in favor of your machine- you have proved that your machine is capable of scrubbing.

“In this modern age that sort of waste is unacceptable”

Again, you’ll use more water (possibly electricity as well if the water is heated electrically) washing dishes by hand than if you were to use a dishwasher that use a little over 13 gallons of water.

Again, you’ll use more water (possibly electricity as well if the water is heated electrically) washing dishes by hand than if you were to use a dishwasher that use a little over 13 gallons of water.

Sean, I'll be honest. Excluding the bake dish, I have a feeling that a certain amount of pre-rinsing is going on in Europe. I'm not saying Lavamat is pre-rinsing, just the average EU person in general. Water should never touch anything prior to going into a dishwasher.

lavamat_jon

Well-known member

Chet,

All European dishwasher use the micro filter system, water is filtered during recirculation and any coarser food residues are drained away if the detergents and enzymes haven’t already done their work in breaking them down. It’s a system that works very well here, cleaning the filters is a quick 2 minute occasional, no-fuss job. Macerators just aren’t used or are necessary here.

Miele for example always used to use the cake test and passed with flying colours each time.

There are reliable and unreliable brands here just as in the USA - but one thing for certain is that most machines nowadays here are very energy and water efficient (and to be honest have been for years). An appliance’s efficiency doesn’t correlate to reliability or build quality.

Pre rinsing is not a practice that is common here. Of course there’s always going to be people who pre rinse at the sink wherever they live in the world, but the general attitude here is to scrape any food scraps into the bin before loading the dishwasher and not to pre rinse. Dishwasher detergents advertise aggressively here to those few who still pre-rinse, but as I imagine as is the same in the USA those people aren’t going to change their mindset. I find it amusing that people buy a dishwasher to save them a job, but still carry on doing that job in addition to then stacking the dishwasher.

The only water I use at the sink as part of cleaning up after dinner is a small amount with washing up liquid (dish soap) to wipe down the surfaces, and a negligible amount of cold water to rinse out any plastic containers, or tins/jars etc that go out for recycling.

Sean,

A machine using more resources than another to do exactly the same job to a high standard is the very definition of waste. You’ve overlooked the point I was making - I fully agree with you that using a dishwasher uses less resources than the sink. Modern dishwashers (and even most European models made in the last 20 years or so) use less than one washing up bowl full of water to do the job. Although I will admit I would personally find it difficult to imagine using even 50l of water to wash dishes manually in a sink - but I suppose if you washed under running water rather than in a bowl, using that amount that could become feasible.

Not intending to create a debate as to who does it better or vintage vs modern, just pointing out that appliances can use little resources and still do the job very effectively, efficiently and reliably. With the way the world is heading we all need to do what we can, and even if resources are plenty wherever one lives it’s still prudent and respectful to nature not to waste precious resources. What may seem as little contribution on a personal level all adds up to a positive contribution as a greater whole.

Jon

All European dishwasher use the micro filter system, water is filtered during recirculation and any coarser food residues are drained away if the detergents and enzymes haven’t already done their work in breaking them down. It’s a system that works very well here, cleaning the filters is a quick 2 minute occasional, no-fuss job. Macerators just aren’t used or are necessary here.

Miele for example always used to use the cake test and passed with flying colours each time.

There are reliable and unreliable brands here just as in the USA - but one thing for certain is that most machines nowadays here are very energy and water efficient (and to be honest have been for years). An appliance’s efficiency doesn’t correlate to reliability or build quality.

Pre rinsing is not a practice that is common here. Of course there’s always going to be people who pre rinse at the sink wherever they live in the world, but the general attitude here is to scrape any food scraps into the bin before loading the dishwasher and not to pre rinse. Dishwasher detergents advertise aggressively here to those few who still pre-rinse, but as I imagine as is the same in the USA those people aren’t going to change their mindset. I find it amusing that people buy a dishwasher to save them a job, but still carry on doing that job in addition to then stacking the dishwasher.

The only water I use at the sink as part of cleaning up after dinner is a small amount with washing up liquid (dish soap) to wipe down the surfaces, and a negligible amount of cold water to rinse out any plastic containers, or tins/jars etc that go out for recycling.

Sean,

A machine using more resources than another to do exactly the same job to a high standard is the very definition of waste. You’ve overlooked the point I was making - I fully agree with you that using a dishwasher uses less resources than the sink. Modern dishwashers (and even most European models made in the last 20 years or so) use less than one washing up bowl full of water to do the job. Although I will admit I would personally find it difficult to imagine using even 50l of water to wash dishes manually in a sink - but I suppose if you washed under running water rather than in a bowl, using that amount that could become feasible.

Not intending to create a debate as to who does it better or vintage vs modern, just pointing out that appliances can use little resources and still do the job very effectively, efficiently and reliably. With the way the world is heading we all need to do what we can, and even if resources are plenty wherever one lives it’s still prudent and respectful to nature not to waste precious resources. What may seem as little contribution on a personal level all adds up to a positive contribution as a greater whole.

Jon

Correct me if I'm wrong, it sounds like there are food bits at the bottom of the dishwasher at the end of the cycle. Without a macerator, the drain pump can only accept food bits up to a certain size- the rest has to be separated out. Whats left sits on top of the grate. Filters should not need cleaning either, it is the job of the dishwashers to be self cleaning for life.

In the Power Clean filter module unless a person wittingly decides not to scrap whole slices of food or intentionally places large unbreakable chunks of food into the dishwasher, food bits slip through the almost grape sized tub protruding louvers encircling the mechanism where they are then pulled into a beefy 1/3 HP (500 watt plus +++) 3450 rpm macerator and ground up into fine particles. A good portion of the water is then pumped into the filter chamber where the ground food accumulates and settles while water exits out through the fine filter. Holes at the bottom of the wash arm spray downward washing the fine filter squares preventing food soils from clogging them or permanently sticking to them. At drain, the filter chamber is pumped out directly- settled soils can not in any way migrate back into the tub- all accumulated soil in the chamber leaves through the machines drain hose and into the homes plumbing. The soil chamber is huge and can hold a LOT of food soil- soil from the worse cases of food bits stuck to every dish possible. In a EU machine I can just imagine the fine filter becoming totally clogged into the main wash. The Power Clean Filter Module stops just short of an insink garbage disposer.

To give you an idea, here is a disassembly of a late model US Power Clean Filter Module. What the vid doesn't do full justice or show how much area volume is inside the soil chamber.

The whole mechanism being changed out in the Kitchen Aid version- I like the big motor and pump size

To get this true self cleaning, true none pre-rinsing design to work you're going to need a bit of water to maximize its full potential.

https://www.repairclinic.com/PartDetail/Pump-And-Motor-Assembly/W10428777/2118886

In the Power Clean filter module unless a person wittingly decides not to scrap whole slices of food or intentionally places large unbreakable chunks of food into the dishwasher, food bits slip through the almost grape sized tub protruding louvers encircling the mechanism where they are then pulled into a beefy 1/3 HP (500 watt plus +++) 3450 rpm macerator and ground up into fine particles. A good portion of the water is then pumped into the filter chamber where the ground food accumulates and settles while water exits out through the fine filter. Holes at the bottom of the wash arm spray downward washing the fine filter squares preventing food soils from clogging them or permanently sticking to them. At drain, the filter chamber is pumped out directly- settled soils can not in any way migrate back into the tub- all accumulated soil in the chamber leaves through the machines drain hose and into the homes plumbing. The soil chamber is huge and can hold a LOT of food soil- soil from the worse cases of food bits stuck to every dish possible. In a EU machine I can just imagine the fine filter becoming totally clogged into the main wash. The Power Clean Filter Module stops just short of an insink garbage disposer.

To give you an idea, here is a disassembly of a late model US Power Clean Filter Module. What the vid doesn't do full justice or show how much area volume is inside the soil chamber.

The whole mechanism being changed out in the Kitchen Aid version- I like the big motor and pump size

To get this true self cleaning, true none pre-rinsing design to work you're going to need a bit of water to maximize its full potential.

https://www.repairclinic.com/PartDetail/Pump-And-Motor-Assembly/W10428777/2118886

lavamat_jon

Well-known member

Sorry Chet, but you are wrong in your hypothesis - on a correctly operating and used dishwasher, no food bits remain on the filter at the end of the cycle and as mentioned before any remaining food scraps and residue that isn’t dissolved by the detergent is flushed down the drain. I have just taken the filter out of mine before posting to check and there is nothing in the sump or indeed either on the coarse mesh or fine microfilter - and it has been a while since I’ve cleaned it.

If you are putting food bits in that are big enough to clog the drain, then you are using the dishwasher wrong - any large food scraps should be scraped into the bin before you load. It is a dishwasher after all, not a waste disposal unit.

Cleaning a filter is really not as big or ardeous a task as some some think it is on here. It’s a 2 minute (if that) occasional job. It’s no different to maintaining the filters on your dryer, cooker hood, vacuum etc… I don’t understand the whole melodramatic aversion to dishwashers having a filter. If anything, priding on simplicity as you do surely adding a macerator is arguably just an extra unnecessary part?

My parents both being disabled very rarely check or maintain their dishwasher filter as recommended, yet it still yields sparkling results every time. I will clean it when I remember (maybe every 6 months) and other than perhaps a stray bit of plastic wrapping or cocktail stick the filter itself is always clean of any particles of foodstuffs and just requires a rinse under some hot water.

The fact remains that you can wash dishes very efficiently and thoroughly with little water and energy, without needing a whole ocean of water to do so. Of course there are different approaches to doing the same job - just wanting to provide factual views from an alternate viewpoint .

.

Jon

If you are putting food bits in that are big enough to clog the drain, then you are using the dishwasher wrong - any large food scraps should be scraped into the bin before you load. It is a dishwasher after all, not a waste disposal unit.

Cleaning a filter is really not as big or ardeous a task as some some think it is on here. It’s a 2 minute (if that) occasional job. It’s no different to maintaining the filters on your dryer, cooker hood, vacuum etc… I don’t understand the whole melodramatic aversion to dishwashers having a filter. If anything, priding on simplicity as you do surely adding a macerator is arguably just an extra unnecessary part?

My parents both being disabled very rarely check or maintain their dishwasher filter as recommended, yet it still yields sparkling results every time. I will clean it when I remember (maybe every 6 months) and other than perhaps a stray bit of plastic wrapping or cocktail stick the filter itself is always clean of any particles of foodstuffs and just requires a rinse under some hot water.

The fact remains that you can wash dishes very efficiently and thoroughly with little water and energy, without needing a whole ocean of water to do so. Of course there are different approaches to doing the same job - just wanting to provide factual views from an alternate viewpoint

Jon

Good cleaning needs up to 16 gallons

Those dishes have to be going in relatively clean or with relatively little soil load to produce the results you describe. I can't imagine detergent being able to dissolve bigger food bits let along in large quantities.

A macerator is a necessary part in every aspect including saving energy. You should not rely on manual clean filters or sump grates- particles need to be ground up, separated, and then flushed down the drain in the same load. Anything less will force loading pre-prep which significantly increases energy use.

Perhaps what you see as dishwasher mis-use is actually the right way to use a dishwasher and I could see how you came to that inference when your design might not allow for proper soil handling. You're simply altering your patterns until the machine you're using produces the great cleaning results you want to see. Coming to the conclusion this is normal and acceptable based on the reduction of energy use. It is no secret the the soil soiled dishes are going into a machine the less water is required to clean them inside the machine.

Granted I'm not there as I have not witnessed or experienced what you have experienced. So I could be wrong. At the same time I do know that when Americans including myself switched to tall tubs the results were not the same as their or my Power Clean Module. A friend of mind even had his spray arm tall tub holes clog.

Only acceptable luck I've ever had with a tall tub is my former MDB Maytag and currently near identical Maytag MDB7979SHZ0 which is based on the Power Clean Filter Module design. It has a macerator, self cleaning fine filter, and can use up to 16 gallons of water with the right options and soil sensing inputs.

https://s3.amazonaws.com/sm-backend-production-attachments/instruction-sheet-w11172665a.pdf

I sure hope you're dishwasher's soil sensor would modify the cycle to 16 gallons of water if the load was dirty enough. Please tell me it can.

https://s3.amazonaws.com/sm-backend-production-attachments/instruction-sheet-w11172665a.pdf

Those dishes have to be going in relatively clean or with relatively little soil load to produce the results you describe. I can't imagine detergent being able to dissolve bigger food bits let along in large quantities.

A macerator is a necessary part in every aspect including saving energy. You should not rely on manual clean filters or sump grates- particles need to be ground up, separated, and then flushed down the drain in the same load. Anything less will force loading pre-prep which significantly increases energy use.

Perhaps what you see as dishwasher mis-use is actually the right way to use a dishwasher and I could see how you came to that inference when your design might not allow for proper soil handling. You're simply altering your patterns until the machine you're using produces the great cleaning results you want to see. Coming to the conclusion this is normal and acceptable based on the reduction of energy use. It is no secret the the soil soiled dishes are going into a machine the less water is required to clean them inside the machine.

Granted I'm not there as I have not witnessed or experienced what you have experienced. So I could be wrong. At the same time I do know that when Americans including myself switched to tall tubs the results were not the same as their or my Power Clean Module. A friend of mind even had his spray arm tall tub holes clog.

Only acceptable luck I've ever had with a tall tub is my former MDB Maytag and currently near identical Maytag MDB7979SHZ0 which is based on the Power Clean Filter Module design. It has a macerator, self cleaning fine filter, and can use up to 16 gallons of water with the right options and soil sensing inputs.

https://s3.amazonaws.com/sm-backend-production-attachments/instruction-sheet-w11172665a.pdf

I sure hope you're dishwasher's soil sensor would modify the cycle to 16 gallons of water if the load was dirty enough. Please tell me it can.

https://s3.amazonaws.com/sm-backend-production-attachments/instruction-sheet-w11172665a.pdf

While it is possible to use as little resources as possible, it is often poorly executed these days. Seems companies these days just like to GM-ification everything, good idea, good layout, terribly executed.

I’ll put it this way and it may be an apples to oranges comparison, but here it goes. Say for example, you have an old Ford truck from the 1990’s with the 300 inline 6 with a cast iron timing gear, simple proven pushrod OHV design. May not be extremely efficient, but continues to run and run and run forever. Then, you upgrade to a newer Ford truck with the Ecoboost V6 which gets good fuel mileage, but here’s one thing they don’t mention in the fine print. Every so often, the timing chains and phasers and glides have to be replaced, intake valves have to be cleaned since there’s carbon buildup do to the GDI design, among other things. What ends up being saved on fuel costs will be spent on repair costs, it’s all fun and games until something more efficient ends up nickel and diming you in repairs that aren’t repaired on something older. While the old Ford truck from the 1990’s gets mediocre mileage, it’ll continue to run and run with little maintenance, only things it will need is fluid changes.

As the saying goes: “If it’s too good to be true, then it probably is”.

I’ll put it this way and it may be an apples to oranges comparison, but here it goes. Say for example, you have an old Ford truck from the 1990’s with the 300 inline 6 with a cast iron timing gear, simple proven pushrod OHV design. May not be extremely efficient, but continues to run and run and run forever. Then, you upgrade to a newer Ford truck with the Ecoboost V6 which gets good fuel mileage, but here’s one thing they don’t mention in the fine print. Every so often, the timing chains and phasers and glides have to be replaced, intake valves have to be cleaned since there’s carbon buildup do to the GDI design, among other things. What ends up being saved on fuel costs will be spent on repair costs, it’s all fun and games until something more efficient ends up nickel and diming you in repairs that aren’t repaired on something older. While the old Ford truck from the 1990’s gets mediocre mileage, it’ll continue to run and run with little maintenance, only things it will need is fluid changes.

As the saying goes: “If it’s too good to be true, then it probably is”.

Best cleaning dishwashers

Hi Chet, I don’t know why you keep going on about power clean dishwashers. They’re not making them any anymore. They’re never going to make them again, everybody knows it was a wonderful dishwasher. I have three of them in my two homes.

As a repair person that deals with people and their appliances every day, one thing is universal. Everybody loves their new dishwashers among my customers. It doesn’t matter whether it’s a Bosch, Maytag KitchenAid, etc. etc. universally very happy with the results of their dishwashers.

There are many testimonials on this site from people who are very critical of dishwashers and yet they love their new machines. Look at the rave reviews on the new Maytag rack how much Bob loves his Bosch dishwasher in Texas Almost everybody says they’ve never had such clean dishes.

The great majority of people in this world want their appliances to use less energy less water and make less noise. Dishwasher manufactures amazing job on these three things machines also continue to be quite durable. you have to remember historically back in the 60s and 70s there were lots of dishwashers that didn’t last five years in the United States and yes, there are dishwashers today that don’t last five years I have thrown away three Samsung dishwashers that were under three years old in the last month, for example.

The KitchenAid dishwashers of old here in the United States from the 50s through the 80s were incredibly well built dishwashers. However, the most frequent service call we got on them was not cleaning well they were all kinds of things would go wrong with them that needed attention. nothing has changed. Modern dishwashers can have problems to.

Reply 51 hi Sean yes you’re definitely getting into apples and oranges when you bring in a 1990s Ford truck into the comparison, however, those engines really didn’t last that long and they made so much pollution and use so much fuel that nobody would even drive them today. When I was working for Domino’s service in 1979, they gave me a brand new Ford van with the 306 cylinder and an automatic transmission, that engine had to be rebuilt because of a failure of one of the cylinders by the time it had 37,000 miles on it things were not that well built in those days, even though it was a rugged engine in principle it really wasn’t that great. And there was no warranty on it like today, the new Pacifica. I just bought has six years and 60,000 mile warranty on it with no extra charge. Manufactures know that things are much better today and they’re willing to give long warranties.

John

Modern cars are easily lasting 100 200 250,000 miles if you take care of them and all the while they’re producing 1/60 of the pollution so it’s really not a bad thing if the vehicle needs to be recycled after 20 years.

Hi Chet, I don’t know why you keep going on about power clean dishwashers. They’re not making them any anymore. They’re never going to make them again, everybody knows it was a wonderful dishwasher. I have three of them in my two homes.

As a repair person that deals with people and their appliances every day, one thing is universal. Everybody loves their new dishwashers among my customers. It doesn’t matter whether it’s a Bosch, Maytag KitchenAid, etc. etc. universally very happy with the results of their dishwashers.

There are many testimonials on this site from people who are very critical of dishwashers and yet they love their new machines. Look at the rave reviews on the new Maytag rack how much Bob loves his Bosch dishwasher in Texas Almost everybody says they’ve never had such clean dishes.

The great majority of people in this world want their appliances to use less energy less water and make less noise. Dishwasher manufactures amazing job on these three things machines also continue to be quite durable. you have to remember historically back in the 60s and 70s there were lots of dishwashers that didn’t last five years in the United States and yes, there are dishwashers today that don’t last five years I have thrown away three Samsung dishwashers that were under three years old in the last month, for example.

The KitchenAid dishwashers of old here in the United States from the 50s through the 80s were incredibly well built dishwashers. However, the most frequent service call we got on them was not cleaning well they were all kinds of things would go wrong with them that needed attention. nothing has changed. Modern dishwashers can have problems to.

Reply 51 hi Sean yes you’re definitely getting into apples and oranges when you bring in a 1990s Ford truck into the comparison, however, those engines really didn’t last that long and they made so much pollution and use so much fuel that nobody would even drive them today. When I was working for Domino’s service in 1979, they gave me a brand new Ford van with the 306 cylinder and an automatic transmission, that engine had to be rebuilt because of a failure of one of the cylinders by the time it had 37,000 miles on it things were not that well built in those days, even though it was a rugged engine in principle it really wasn’t that great. And there was no warranty on it like today, the new Pacifica. I just bought has six years and 60,000 mile warranty on it with no extra charge. Manufactures know that things are much better today and they’re willing to give long warranties.

John

Modern cars are easily lasting 100 200 250,000 miles if you take care of them and all the while they’re producing 1/60 of the pollution so it’s really not a bad thing if the vehicle needs to be recycled after 20 years.

lavamat_jon

Well-known member

Even 16 litres is more than enough, 16 gallons is just crazy and wasteful.

You’ve actually seen photographic evidence of what my own, very efficient dishwasher cleans on a daily basis yet still claim it’s impossible or that I’m altering my routine to achieve the results? Where’s the sense in that . Dirty dishes go into the machine, any large loose scraps scraped into the bin, clean dishes come out. Short of dumping the whole contents of the meal into the dishwasher instead of eating it I struggle to comprehend what standards you actually expect to achieve yet alone why you would that much water.

. Dirty dishes go into the machine, any large loose scraps scraped into the bin, clean dishes come out. Short of dumping the whole contents of the meal into the dishwasher instead of eating it I struggle to comprehend what standards you actually expect to achieve yet alone why you would that much water.

On another thread you say you mostly eat frozen convenience meals. Do you cook from scratch on a daily basis? No shame if you don’t, cooking isn’t for everybody, but I do cook from scratch everyday and the dishwasher copes with any pot, pan, roasting dish etc thrown at it with ease. I’ve yet to put anything back in for a second round. The dishwasher would have a much easier life if we ate convenience food everyday.

Perhaps filters vs macerator is a personal preference, but it is wrong of you to say they don’t work as the fact is they do, and again with (I repeat) very little actual maintenance required.

As another saying goes, you can lead a horse to water but you can’t force it to drink. I will happily continue doing dishes with responsibility and respect to the world’s resources whilst getting great results - whether or not you choose to believe that plenty of people already do that is up to you.

Enjoy your day.

Jon

You’ve actually seen photographic evidence of what my own, very efficient dishwasher cleans on a daily basis yet still claim it’s impossible or that I’m altering my routine to achieve the results? Where’s the sense in that

On another thread you say you mostly eat frozen convenience meals. Do you cook from scratch on a daily basis? No shame if you don’t, cooking isn’t for everybody, but I do cook from scratch everyday and the dishwasher copes with any pot, pan, roasting dish etc thrown at it with ease. I’ve yet to put anything back in for a second round. The dishwasher would have a much easier life if we ate convenience food everyday.

Perhaps filters vs macerator is a personal preference, but it is wrong of you to say they don’t work as the fact is they do, and again with (I repeat) very little actual maintenance required.

As another saying goes, you can lead a horse to water but you can’t force it to drink. I will happily continue doing dishes with responsibility and respect to the world’s resources whilst getting great results - whether or not you choose to believe that plenty of people already do that is up to you.

Enjoy your day.

Jon

So John, why don't you ditch your Power Cleans for a modern tall tub? You claim modern tall tubs clean even better with less water, noise and energy. So why not do the right thing and save the planet? You can even hand your Power Cleans over to me since I don't mind noise, water and less clean dishes.

Dishwasher longevity and reliability peaked in 1983 to 1991 especially with the introduction of the GE Perma-Tuff Potscrubber which was the pinnacle of it all.

Other than those being forced into using modern machines I have no doubt there is a substantial number of folks who like the increase in capacity and quietness tall tubs offer on the premise most of the dishware cleaning is already done beforehand. The inability of tall tubs and manual clean filter system to handle food bits does not make itself known to the user. You have to realize that, tragically, a large number of the population has grown up with dishwashers without fine filters, no or insufficient main wash heating, broken macerators, deliberately shortened main wash times, insufficient water change outs, short cycle times, poor water distribution, no upper wash arm (I'm excluding GE's pop up tower here), no power shower, bargain dish-washing detergents, hard water, undersized detergent cups, or a combination of all these things which has permanently conditioned people to pre wash and pre-prep their dishware to varying yet significant degrees.

Prerinsed dishware isn't going to matter in a tall tub, of course people will see whats next that being reduced noise and the feel good of perceived energy savings deriving hedonic fulfillment from these gains.

The Power Clean on the other hand with reasonable time, enough hot water and good detergent will out clean anything being able to provide a true level minimal dish prep. Scrape, load, and wash. You should not even have to pre-treat pots and pans. Load and wash. Water should never touch the vast majority of dishware prior to turning the machine on. The WP PC is capable of doing just that. As all dishwashers should.

Dishwasher longevity and reliability peaked in 1983 to 1991 especially with the introduction of the GE Perma-Tuff Potscrubber which was the pinnacle of it all.

Other than those being forced into using modern machines I have no doubt there is a substantial number of folks who like the increase in capacity and quietness tall tubs offer on the premise most of the dishware cleaning is already done beforehand. The inability of tall tubs and manual clean filter system to handle food bits does not make itself known to the user. You have to realize that, tragically, a large number of the population has grown up with dishwashers without fine filters, no or insufficient main wash heating, broken macerators, deliberately shortened main wash times, insufficient water change outs, short cycle times, poor water distribution, no upper wash arm (I'm excluding GE's pop up tower here), no power shower, bargain dish-washing detergents, hard water, undersized detergent cups, or a combination of all these things which has permanently conditioned people to pre wash and pre-prep their dishware to varying yet significant degrees.

Prerinsed dishware isn't going to matter in a tall tub, of course people will see whats next that being reduced noise and the feel good of perceived energy savings deriving hedonic fulfillment from these gains.

The Power Clean on the other hand with reasonable time, enough hot water and good detergent will out clean anything being able to provide a true level minimal dish prep. Scrape, load, and wash. You should not even have to pre-treat pots and pans. Load and wash. Water should never touch the vast majority of dishware prior to turning the machine on. The WP PC is capable of doing just that. As all dishwashers should.

@Lavamat: I have no doubt your dishwasher cleaned that bake pan, loaded as is. However, you have an excellent example of soil removal from just one surface, not soil handling and or soil elimination of the machine itself. All that pan does is turn the water red/brown in color. (forgive my cynical nature here)

Soil handling and soil elimination comes in three parts:

1) being able to load a used salad bowl and cooked on egg in a stainless pan and not have any of the food bits be at the bottom of the machine at the end of the cycle and not have any of it be in the fine filter of the machine.

2) How would your dishwasher adapt or handle every single plate, pan, bowl, dish, cup and utensil looking like that bake pan inside and out under an extreme Bobload condition? Would there be enough water to carry away all that soil? Would there be enough water use and change outs in the cycle such that the final rinse water is crystal clear, clean enough to drink without flavor, minus rinse aid? (forgive my analogy)

3) The ability to stop macerated particles from ending up on surfaces at the end of the cycle. This is where the final filter comes in, and from what I'm seeing both your machine, my machine and a Power Clean module do that with excellence so I think we can all agree on #3 being superb.

I used to cook most of my meals from scratch, but after buying a Sharp R-21LCFS commercial microwave oven experiencing profoundly even cooking without splatter, drying, burning, or temperature gradients at full 1000 watts of output power along with its understandable easy to use nature I became deeply smittened switching over entirely canned, frozen and pre-made meals. The time savings, ease, convince, tasty and congenial outcome has me psychologically addicted.

As of late that is changing primarily because of farmer markets I've started to cook some of my own meals again relying less on my microwave oven.

Soil handling and soil elimination comes in three parts:

1) being able to load a used salad bowl and cooked on egg in a stainless pan and not have any of the food bits be at the bottom of the machine at the end of the cycle and not have any of it be in the fine filter of the machine.

2) How would your dishwasher adapt or handle every single plate, pan, bowl, dish, cup and utensil looking like that bake pan inside and out under an extreme Bobload condition? Would there be enough water to carry away all that soil? Would there be enough water use and change outs in the cycle such that the final rinse water is crystal clear, clean enough to drink without flavor, minus rinse aid? (forgive my analogy)

3) The ability to stop macerated particles from ending up on surfaces at the end of the cycle. This is where the final filter comes in, and from what I'm seeing both your machine, my machine and a Power Clean module do that with excellence so I think we can all agree on #3 being superb.

I used to cook most of my meals from scratch, but after buying a Sharp R-21LCFS commercial microwave oven experiencing profoundly even cooking without splatter, drying, burning, or temperature gradients at full 1000 watts of output power along with its understandable easy to use nature I became deeply smittened switching over entirely canned, frozen and pre-made meals. The time savings, ease, convince, tasty and congenial outcome has me psychologically addicted.

As of late that is changing primarily because of farmer markets I've started to cook some of my own meals again relying less on my microwave oven.

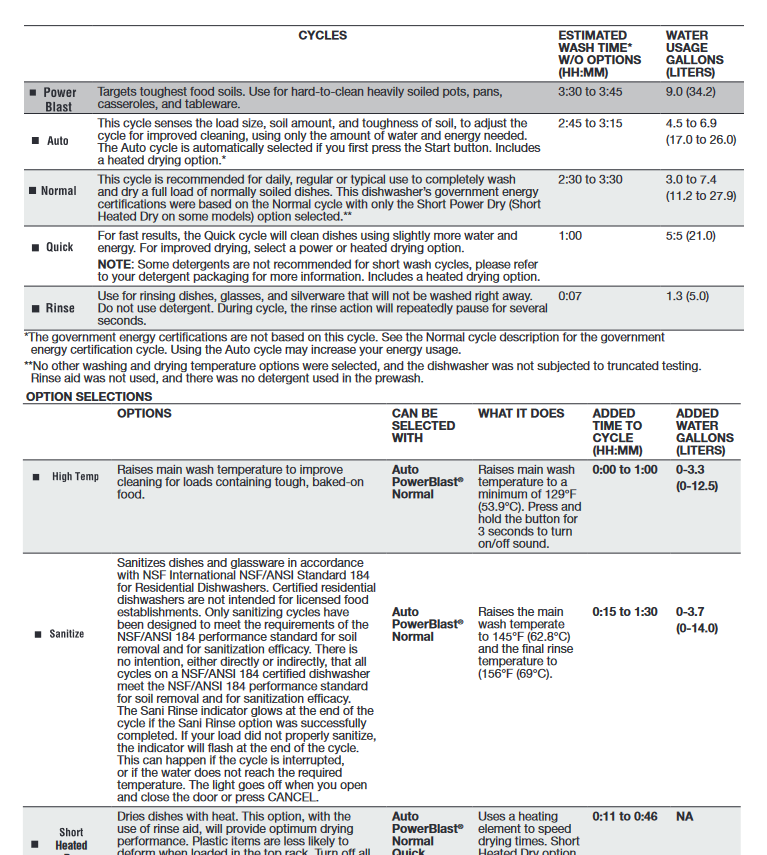

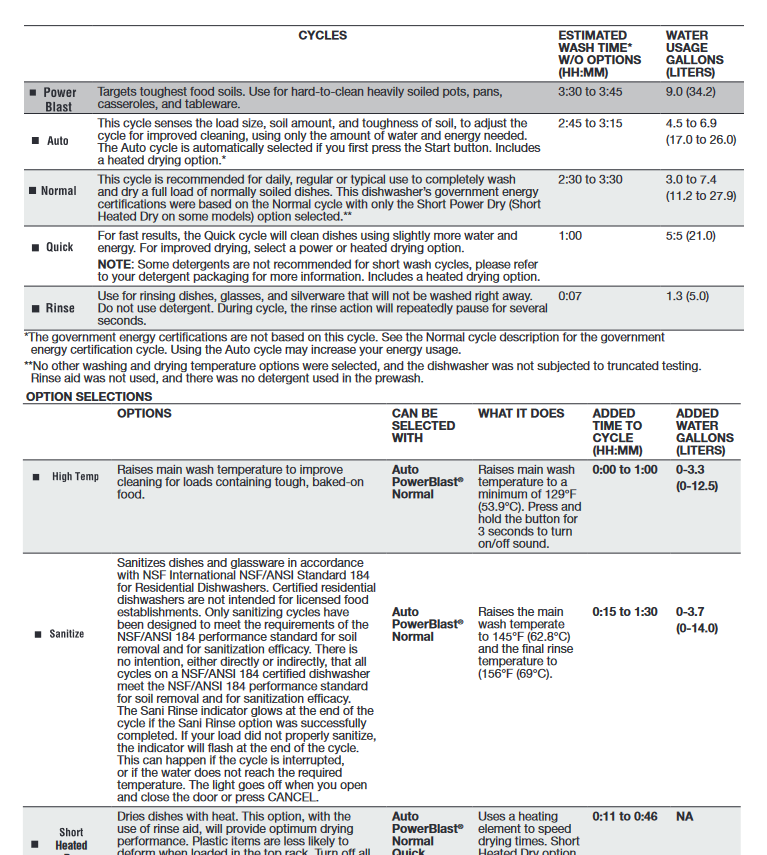

My Dishwasher Maytag MDB7979SHZ0

Here is my dishwasher. On normal without options it uses 3 gallons of water, but on Powerblast with options and food soil it can go well above 9 gallons.

16 gallons is not wasteful at all when its required. Whirlpool seems to think so, and I can understand why. You need water to carry soil away.

Despite everything it still can not outperform the Power Clean Filter Module but does perform well over all.

No filter to clean.

Here is my dishwasher. On normal without options it uses 3 gallons of water, but on Powerblast with options and food soil it can go well above 9 gallons.

16 gallons is not wasteful at all when its required. Whirlpool seems to think so, and I can understand why. You need water to carry soil away.

Despite everything it still can not outperform the Power Clean Filter Module but does perform well over all.

No filter to clean.

hoover1100

Well-known member

Pardon the intrusion..

But to answer your questions based on my modern, energy and water efficient Miele without a macerator;

"1) being able to load a used salad bowl and cooked on egg in a stainless pan and not have any of the food bits be at the bottom of the machine at the end of the cycle and not have any of it be in the fine filter of the machine"

Yes, my machine manages to do this without leaving any traces of food easily

"2) How would your dishwasher adapt or handle every single plate, pan, bowl, dish, cup and utensil looking like that bake pan inside and out under an extreme Bobload condition? Would there be enough water to carry away all that soil? Would there be enough water use and change outs in the cycle such that the final rinse water is crystal clear, clean enough to drink without flavor, minus rinse aid? (forgive my analogy)"

Again, my machine manages all of the above, results are always spotles, final rinse crystal clear, filter empty and I always cram it full and never pre-rinse a thing.

Not only do I never pre-rinse a thing, I have to admit I'm a bit lazy when it comes to scraping large and solid particles before loading. From what you have described of the kind of particles which would not be removed in this "power clean" dishwasher, it sounds like the only food particles that would be left behind in my machine would also be left behind in the power clean. One difference appears to be that with this power clean design I would then have to reach in and pick these bits out by hand, whereas in my machine on the rare occasion large solid pieces of food are left in the filter I can just lift it up, shake it over the bin and put it back in without having to touch the food particles

But to answer your questions based on my modern, energy and water efficient Miele without a macerator;

"1) being able to load a used salad bowl and cooked on egg in a stainless pan and not have any of the food bits be at the bottom of the machine at the end of the cycle and not have any of it be in the fine filter of the machine"

Yes, my machine manages to do this without leaving any traces of food easily

"2) How would your dishwasher adapt or handle every single plate, pan, bowl, dish, cup and utensil looking like that bake pan inside and out under an extreme Bobload condition? Would there be enough water to carry away all that soil? Would there be enough water use and change outs in the cycle such that the final rinse water is crystal clear, clean enough to drink without flavor, minus rinse aid? (forgive my analogy)"

Again, my machine manages all of the above, results are always spotles, final rinse crystal clear, filter empty and I always cram it full and never pre-rinse a thing.

Not only do I never pre-rinse a thing, I have to admit I'm a bit lazy when it comes to scraping large and solid particles before loading. From what you have described of the kind of particles which would not be removed in this "power clean" dishwasher, it sounds like the only food particles that would be left behind in my machine would also be left behind in the power clean. One difference appears to be that with this power clean design I would then have to reach in and pick these bits out by hand, whereas in my machine on the rare occasion large solid pieces of food are left in the filter I can just lift it up, shake it over the bin and put it back in without having to touch the food particles

Do you have pictures and a model # to your Miele?

My Maytag dishwasher has both a macerator and fine filter.

I can't picture a machine being able to seriously clean without either.

Yes food gobs that are to big to go through the Power Clean louvers have to be picked out by hand but that should be very rare- big bits should be scrapped off. The rest is handled well by the power clean. I can't see many medium sized bits of food that can get into a Power Clean leaving a Miele.

My Maytag dishwasher has both a macerator and fine filter.

I can't picture a machine being able to seriously clean without either.

Yes food gobs that are to big to go through the Power Clean louvers have to be picked out by hand but that should be very rare- big bits should be scrapped off. The rest is handled well by the power clean. I can't see many medium sized bits of food that can get into a Power Clean leaving a Miele.

hoover1100

Well-known member

Yes it's a Miele G 645 SC, not sure of the exact age as I bought it 2nd hand.

I have attached a picture, I would show you inside but it's currently half full of dirty dishes so not a particularly pleasant sight

According to the specs it uses 13L of water per cycle, 17L on a cycle with a pre-rinse is selected, it does 2 rinses on all cycles.

I have attached a picture, I would show you inside but it's currently half full of dirty dishes so not a particularly pleasant sight

According to the specs it uses 13L of water per cycle, 17L on a cycle with a pre-rinse is selected, it does 2 rinses on all cycles.

Similar threads

- Replies

- 5

- Views

- 403

- Replies

- 2

- Views

- 886

- Replies

- 12

- Views

- 1K

- Replies

- 80

- Views

- 3K